LED billboards are the ultimate scale-model of digital media advertising. Few projects are as logistically complex as those erected over busy urban thoroughfares, and none are as busy or complex as Times Square, where (pre-COVID) 380,000 pedestrians – mostly tourists – pass through each day. Add to this 115,000 drivers and you arrive at an audience of unrivaled mass. Bringing advertising impressions to this audience is a key factor for ownership. Timing is everything, and each day of delay creates a revenue vacuum that few owners will brook. For this reason, coordination of large-format digital media advertising signage is always mission critical to their respective CPM schedules.

“It costs between $1.1 and $4 million a year to lease advertising space in Times Square. In contrast, a Times Square billboard cost for a day can start at $5,000 and go up to well over $50,000. Moreover, it can cost up to $3 million per month to advertise on Time Square’s largest billboards.

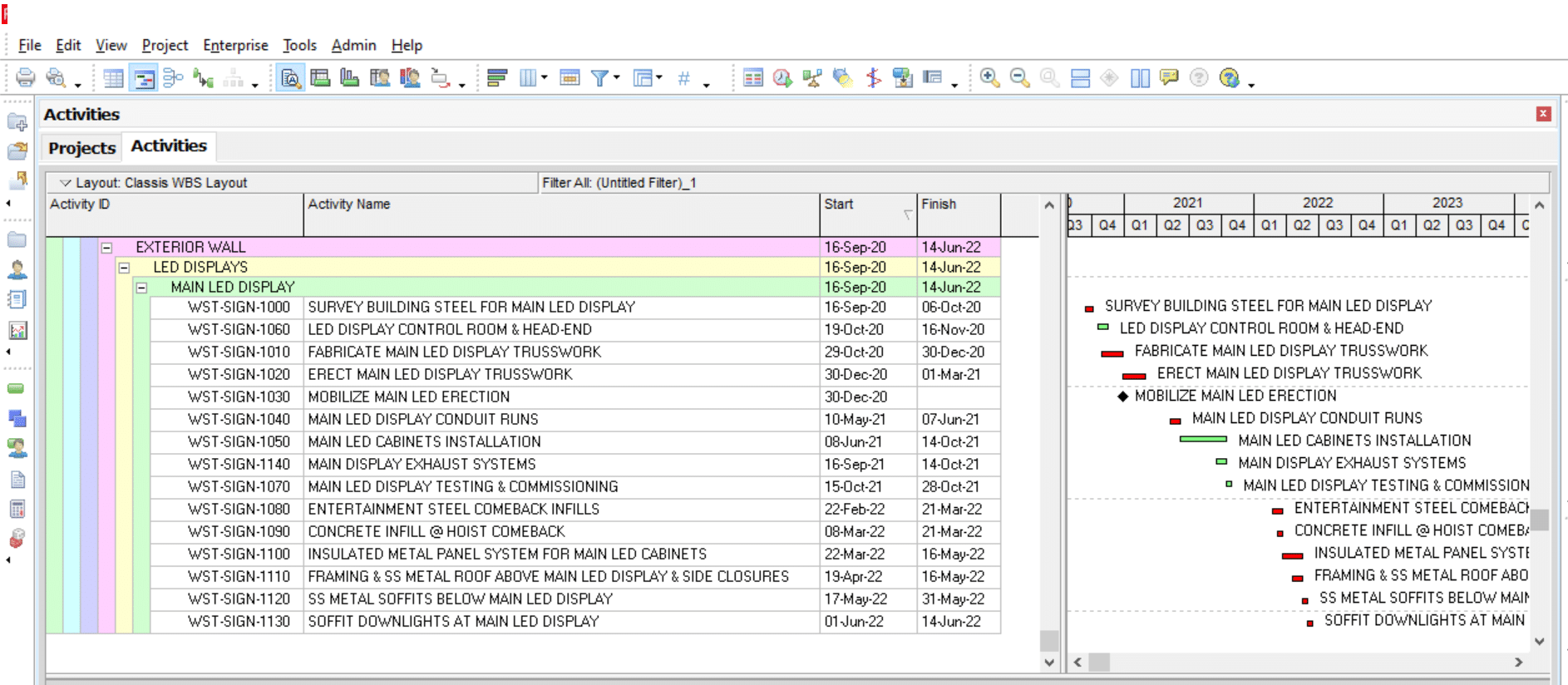

Any trades-person who’s been to Times Square must wonder how those epic multi-story digital media advertising screens are put together, and what that project logic would look like in a construction schedule. From a scheduler’s perspective, some interesting means and methods are what need to be represented in the master schedule – from preconstruction through erection. The complexity of coordination is near the top with any scope of work we represent as schedulers.

Project logic for large-format LED billboard includes coordination driving logistics, and installation of all structural, MEP, and metal trades. Given all those moving parts, all of them must be diligently approached and detailed in the schedule from that perspective. This is especially true of cantilevered systems, as opposed to a standing roof sign, for instance.

Coordination of large format digital media advertising structure begins with engineered drawings of the building structure that will support the load of the truss and LED cabinets. The screens, or LED cabinets aren’t particularly heavy, nor are the metal trusses. Of equal or more concern are the wind-loads that must be sustained. The sign manufacturer will work closely with structural engineers to determine the necessary program.

“Logistic coordination is an early scheduling requirement for any job-site, and the plan must take into consideration the signage program.

Preconstruction digital advertising media activities are given full representation in the baseline schedule. All submittal and approval cycles are shown, as is fabrication, which should have plenty of float. In all likelihood, the feasibility of the sign program was vetted and developed before the baseline existed. Accordingly, digital media advertising submittals seldom go through more than two or three cycles of review.

The digital media advertising manufacturer should verify during preconstruction that the structural support design and fabrication drawings facilitate his installation – that attachment points are aligned, and there are no clashes or program conflicts. It is in his best interest to visit the site to witness the structural support work as it is installed – and sign-off on the locations.

The manufacturer knows what the tolerances are for the support work. If they are very narrow, the signage support drawings should be overlaid over the steel shop-drawings in order to ensure design conformity. Failure to do so could miss disruptive program conflict that only a jackhammer, coring-drill, or welding torch can reconcile.

Once satisfied with the structural steel layout and attachment points, the manufacturer can release the miscellaneous metal truss-work for dimensioning. On cantilevered signs, lightweight welded steel trusses are employed to attach to anchor bolts and/or concrete or steel building structure. Lead for the truss-work may average 12-16 weeks from release time for fabrication. The shop will make it well in time for delivery installation, but not too early that they have to store or warehouse it.

The truss-work can be attached to the building along with its cat-walks and stairs, which facilitate installation. These are likely assigned to miscellaneous metal trades. All digital media advertising signage must be coordinated with any work above – such as concrete or curtain wall, and protect pedestrians or workers below. When there are one-half million passersby daily, this is no small feat. Optimally, all concrete work is complete, and the curtain wall has surpassed the top of the signage. If anchor bolts are used, the truss base-plates holes will often be slotted to allow for a few inches variance in anchor bolt layout.

Once the truss-work and catwalks are installed and MEP connections ready, the delivery date of the equipment should be ascertained. As the equipment is installed, power is run to a disconnect switch, low-voltage to control room head-end, and finally ductile air systems that cool the equipment. The entire system is wrapped with sheet-metal, waterproofed, and closed with access and fixed panel systems behind. Lastly, lighting fixtures are installed to complete the installation.

There are also considerations – or rather ‘schedule constraints’ that have nothing to do with the work itself, such as a permanent power source. Most buildings go up before permanent power is run, using temporary power sources for the construction phase. At a certain point, unreliable temporary power is no longer feasible, and the building must be readied for new service. This time tends to coincide with completion of a waterproof building envelope and enclosure that utilities require.

Permanent power is a driver of energizing the LED cabinets. The digital video equipment is sensitive to fluctuations or spikes in a temporary service that could damage or destroy the components: a flickering billboard sign is ownership’s worst nightmare. Truss work and misc-metal is not affected by permanent power, only the energization and onlining of the digital advertising media is: equipment may be installed and programmed on temporary power.

Another constraint is the notion that the billboard generates revenue. Ownership relies on the timely energizing of the signage by a milestone date and has leasing contracts with advertisers. Naturally, if this date is eclipsed, there is potential for delay claims.

The key to creating sound signage project logic is to coordinate early with related trades in the baseline to determine critical path activities. A scheduler has to push for this effort, as PMs tend to give it scant attention. This is especially so when the digital advertising media vendor contracts directly with the owner, which is typically the case.

Having the network established in the baseline can benefit forward-pass projections and create accountability for potential delays that are not the fault of the contractor. Facing a back-charge of $50,000/day, I should think it behooves any contractor to practice due diligence scheduling digital media advertising.