We have defined what shop drawings are traditionally thought of, which begs the question: what shop drawings are not, or may not be. The quality of shop drawings varies considerably among contractors. All must be judged on their own merits and specific application. Shop-drawings are never an end in themselves: they must be coordinated with adjacent program, which includes providing access and clearance for these programs.

Although a designer may approve or stamp drawings “furnish as corrected” or “no exception taken,” etc., this distinction does not speak to the veracity of the drawings; it is merely part of the oversight review process. More importantly, he has no contractual responsibility for the accuracy or viability of the drawings. The level of scrutiny by oversight designers varies widely.

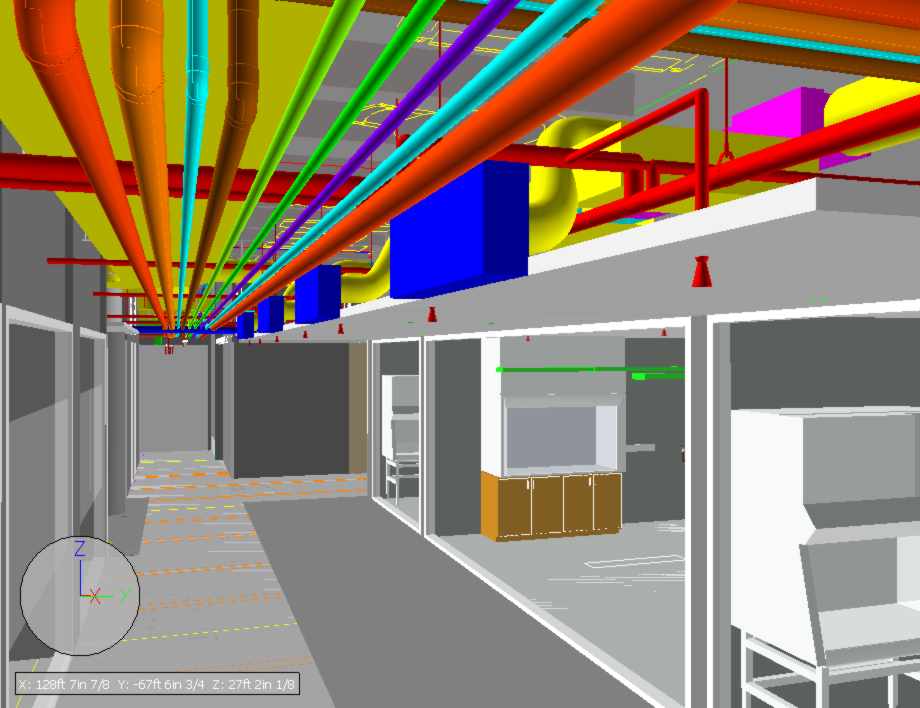

Shop drawings do not exist in a vacuum: they begin with schematics, evolve into dimensioned fabrication drawings, and are used in the MEP coordination effort. They also typically are accompanied by general performance specifications and materials that must be compliant with the project specifications. For example, our hypothetical duct system submittal would include a SMACNA book. In many cases, a mock-up may also be required for inspection. Finally, are issued “red-lined” as-builts, or corrected to show actual works. This last stage is critical to the end-user for his maintenance plan.

For products that are manufactured according to their own standard designs, suppliers typically have a library of specifications at the ready, on their website. However, for customizations, shop drawings will have to be modified accordingly. Many manufacturers prefer not to deviate from their standard specifications, and are loath to do so, without a costly upcharge. Think of a custom suit, as opposed to one off-the-rack: factories are tuned to manufacture standard issues; customizations invariably gum up the assembly line.

Shop drawings are an integral part of the build-out process. They are meant to facilitate the work by the contractors who prepare them, and to convey their intentions to other team members whose program it is related to, integrated with, or may be affected by. Too many general contractors act as a pass-through during their sub-contractors’ shop drawing submittal and approval process, when they should be closely vetting them. That level of scrutiny is reserved for general contractors who aspire to a higher level of integrity.