The present state of CPM construction scheduling specifications is notoriously fragmented, with little hope of standardization in the future. Each entity seemingly has its own esoteric litany of requirements for project baselines and reporting methods of their schedules. They are all over the map: from feeble two-page blurbs that small architects include in their specifications, to the exhaustive and controlling GAO and DOD, and everywhere in between.

Fragmentation never trumps standardization in the software scheduling specifications industry, yet every agency seemingly tries to break the mold with their own brand of vigorous reporting procedures that are by and large ends in themselves (rarely read by stakeholders). Some will even try to stick the scheduler with services he may not even proffer; such as tedious cost-loading, risk assessment or mitigation strategies.

That’s sort of like buying a tank of gas and expecting a free car to pour the gas into.

The emphasis on tedious scheduling specifications requirements comes from negative past experiences with incompetent schedulers. Stakeholders must have felt it necessary to establish more controls on the scheduler with the expectation that he would perform better, whereas the effect only saddled the scheduler with more responsibility – putting him even further behind the eight-ball. Little did they realize that merely implementing onerous requirements on their projects will in no way ensure any degree of adherence by the scheduler.

If schedulers cow-towed to every whimsy of each scheduling specifications drafter, they would not be able to maintain a livelihood above the poverty-line. In the same way, you wouldn’t walk into a Chinese restaurant and expect everything on the menu to accompany your entrée.

Lousy schedulers will be unsuccessful regardless of the requirements, whereas good schedulers operate most efficiently using their own means and methods. This is a concept that is generally ignored by specifiers and stakeholders, who seldom even peruse their own specifications, which often are merely distillations or transpositions of other agencies. Surprisingly, even construction managers are prone to ignore the more superfluous requirements, as they require more oversight of them, often for things they don’t understand.

Once the focus shifts from the critical path, to the minutiae of the requirements, you begin to miss the forest for the trees.

Alternatively, many schedulers simply ignore tedious scheduling specifications with varying degrees of success. They ignore them because

- They are not consistent with the service they typically provide or as stated in their proposal, and involve significant extra effort.

- They require them to learn new means and methods to service their client, often for services that are one-off, or unlikely to be repeated

- They know the players and landscape of the project: for example, if the general contractor is known to be unresponsive, and the client difficult, the scheduler can expect extra effort to obtain the information he needs to facilitate his work.

- They are not part of the scheduler’s proposal, whether by omission or exclusion. Just as many subcontractors do – when a scheduler bids on a project with exhaustive requirements, he is more likely to either exclude the requirements, or issue his own scope of work in lieu of the specifications.

This latter instance is the most debilitating for a scheduler, because it takes him out of his comfort and control zones, into unknown territories of risk. Successful schedulers become successful by standardizing their optimized systems, such that they don’t have to reinvent the wheel for every project. Once the recipe, or specifications change, they can expect to deliver labor-intensive custom products for each project, which is the antithesis of the tried and true that made them successful.

The result is that many specification requirements are simply ignored, or under-delivered. Entities known for having cumbersome specifications may have these demands reflected in the bids they solicit. That is, they pay a premium for requiring a scheduler to do custom work. This is perfectly understandable: you wouldn’t visit a chair factory that made only red chairs, and expect them to retool their entire manufacturing process to make one blue chair at the same cost as their red chairs. The same holds true in construction scheduling specifications.

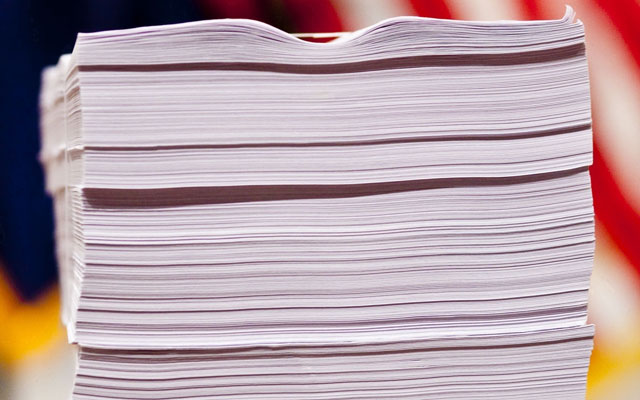

(feature image: the Obama Care Bill, 22,214 pp.)