Reinforced Concrete Building CPM Scheduling for Success

Reinforced Concrete Building – if you’re a construction person living or working in most any metropolitan area in the US northeast, than you can’t help but notice the impressive volume of reinforced concrete (RC) towers popping up. If you’re lucky enough to work as a CPM scheduler in one during construction, then you get to be part of a complex process of several moving parts that is instructive and enjoyable to watch.

Unlike precast plank, and CIP/structural steel superstructures, reinforced concrete building relies on critical coordination of several moving parts – such as hoists, tower cranes, monorail, and spider cranes, with riggers, lathers, and concrete form, shore, pour, strip and reshore teams, including foremen, managers, supers, safety personnel, and hoist operators. Maintenance and protection of traffic (MPT) is often also required by Department of Transportation, as most any urban pick will involve closing or partly closing a public sidewalk, lane, or thoroughfare.

The entire process relies on the careful synchronization of some critical elements occurring in a set sequence that is called out in a logistics drawing by an engineer, and issued with the construction documents. Operators and contractors may not vary the sequences that have been approved by local agencies before a revised logistic plan is issued and approved. The process tends to lose time, which is why a sensible initial plan reduces the need to restrategize logistics.

From the ground upward, any reinforced concrete building will require a staging area for hoisting bar, forms, outriggers, periforms, and concrete is the hub of activity. The scaffolding systems will vary according to building design. As the building goes up, smaller equipment can feed material to the site. Once MPT is secured, and safety and equipment inspections made, a tower crane can begin flying material up to the working platform, where material is staged before it is set in place by as many lathers, carpenters, masons, and concrete workers will fit the area without compromising safety.

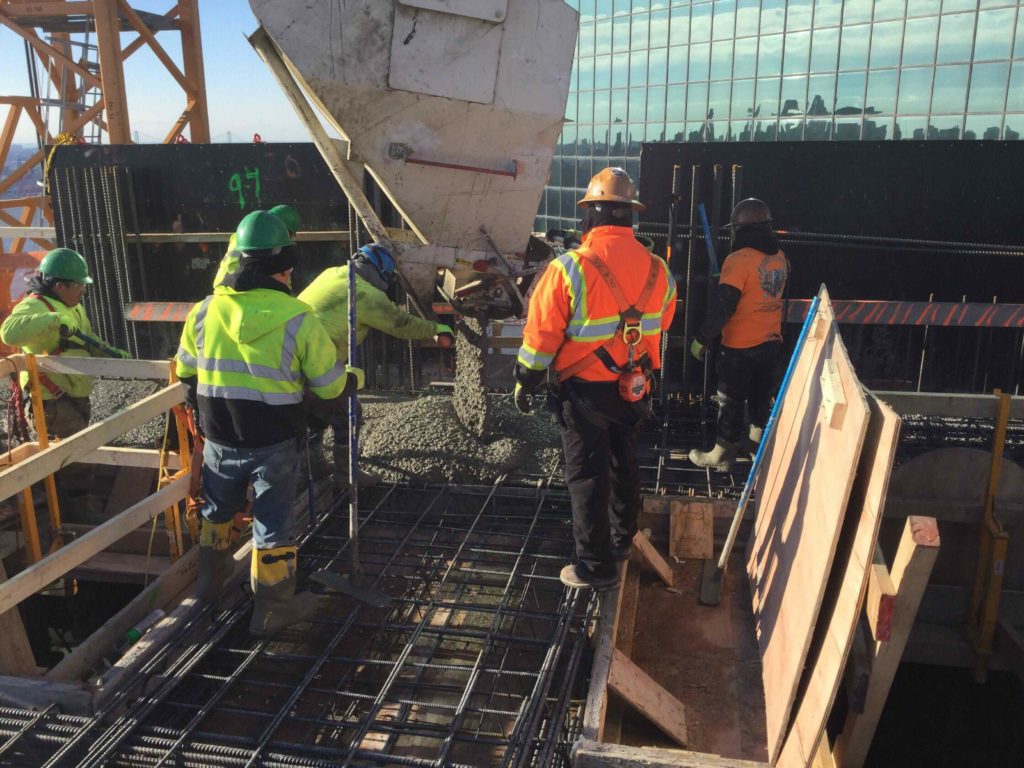

A separate process is set up for concrete pours, where the crane sends up 2-3 yard buckets filled with concrete to be poured for vertical columns and/or slab and shear wall. It must be said, all of this takes place as safely, quickly and efficiently as possible. Considering the number of people on hand for a 200 CY pour, its miraculous that more things don’t go wrong. The fact is, more things are at risk of going wrong before the pour can start. Let the schedule not be affected by any of them!

- Weather is right: if it’s inclement, pour may be postponed. If it’s too windy, the crane cannot be let out. In the winter, we tent and preheat the pour envelope, rather than simply throw in admix. Even then, the plant may struggle to bring the mix to temperature

- Safety and personal protection and equipment (PPE) inspections have been made, and passed all.

- Tools and equipment have passed inspection.

- Insurances validated

- Inspector at the plant has sampled the pour to ensure it complies with the engineer’s design mix, and the form and lath work has passed.

- Blanks and ‘cans’ for slab penetrations and sleeves have been placed and secured within the assembly according to the latest set of drawings.

- Curtain-wall embeds are placed

If you pass a reinforced concrete building going up and you hear the sound of a chipping hammer, you can bet some penetration(s) was overlooked for the pour. If the penetration was a sizable one, there may be reinforcing bar in its path. A relocation or revised structural detail may be required to correct it.

The scheduler will be able to represent the process of a reinforced concrete building going up and its projected trajectory with carefully repeated sequence of operations. In addition to the above sequences:

- Coordinate sequencing of hoist and crane jumps. The hoist equipment is used to bring workers and smaller equipment and materials as high as possible below the topside, or working platform. This distance will be specified in the design and control documentation.

- The crane is jumped to within a given distance from the working deck. This distance is also specified in the design and control documentation.

- Once the concrete has passed preliminary compression tests, the form work is stripped and slab reshored, as preparations made for the next.

The frequency between hoist and crane jumps vary. The best time to jump them is during an inactive period – such as nights, or early morning. Tower cranes are jumped less frequently, and in higher denominations, e.g., every eight floors (crane), as opposed to every other (hoist).

Following the superstructure, curtain-wall will follow the concrete work, beginning with shimming at the embed locations. The distance from the working platform that the curtain wall may go up is also regulated. Once the building is topped off, it’s a race to get the elevators online. When the elevators are inspected, the crane and hoist may be demobilized, and the curtain wall system run up in the openings.

Contractors pride themselves on the speed with which they can run floors up a building. A general rule of thumb is one-week per floor. Naturally, shear walls can add duration to a typical form and pour, and must be taken into account. Some buildings have more complex architectural and MEP layouts, and require more time.

Thus, reinforced concrete buildings involve every trade: mechanical, electrical, and plumbing to set their sleeves, carpenters for formwork, lathers, and the concrete pour team. The efficacy of their work will pay dividends down the line when fit out teams arrive to run their pipe through the penetrations provided in the slab.