Critical Path isn’t always the Longest Path

Most CPM schedules use a critical path as the sole and chief determinant of a given construction project’s time performance and outcome. CPM scheduling software is developed to focus on the critical path as the most useful and efficient means of time management, and accordingly, schedulers learn to adhere to this simple and ready theory. Yet, if degree of accuracy or past performance are any indicator of the status quo, then it must be said that singular focus on the critical path is an inefficient means of project control.

Singular focus on the critical path ignores other float paths and

- Allows no facility to factor other float paths that are catching up to the longest path

- Does not take into consideration the effects of changes on resources, such as congestion, or trade stacking, or even availability of manpower from respective trades

- Does not consider the cost or utility of expediting service or equipment (red-labeling)

- Is a practice virtually unrepresented by risk assessments and risk factors

- Precludes timely mitigation and recovery efforts

- Ignores a more holistic approach to project delivery

We know that some ¾ of general contractors have their project managers preparing CPM schedules. Most of these project managers lack any formal schedule training, and can demonstrate only limited operability in CPM software. This may be fine for projects that don’t rely on CPM schedules for time management and reporting, but it seldom serves any larger purpose. Conversely, schedulers tend to lack field experience.

“75% of contracts have untrained personnel preparing their schedules. At least 75% of all building projects do not make deadline. Any questions?

Despite standard practice, many schedulers are hard put to define ‘critical path:’ for all intensive purposes, any activity with a total-float value of 0 or less, resides on a critical path. In many cases, and with larger and more complex efforts, there may be multiple critical paths. Indeed, Primavera 6 can be set to track multiple float paths, all of which can end in milestones, or a simple sort by Total Float can render the same. Thus, when people ask “what is the critical path,” they really mean the ‘longest path,’ or the path that leads to the earliest possible turnover date.

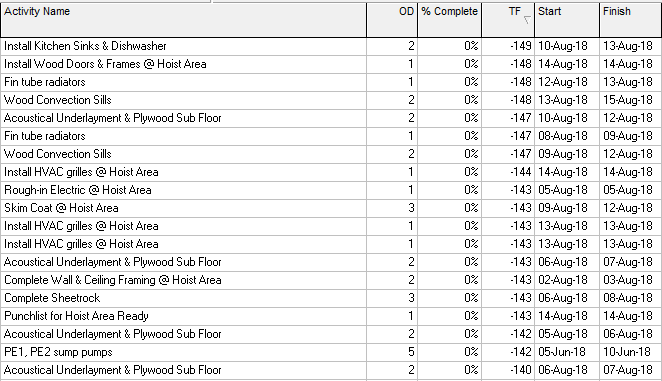

Although there are few days separating them, the activities in the chart below plot several distinct critical float paths

- Fit-out completion of an apartment

- HVAC air balancing (HVAC grilles)

- Elevator certificate

Multiple float paths

The above project has dynamic multiple float paths that are subject to slip. Tracking these multiple critical paths is essential for most any project that has more than one critical trajectory. Focusing only on one aspect denotes oversight. The reasons for this are several:

By focusing only on the longest path, the trajectory of other float paths are overlooked, and may be allowed to languish and cause delay impacts of their own, or even become part of the longest path – missing the forest for the trees, as it were. Such schedules are the product of those who are either not properly trained in CPM scheduling, or lack training altogether. This circumstance is typically a factor of an employer or scheduler refusing to make the requisite investment in training.

Over-reliance on the critical path denotes a lack of understanding of the schedule as an instrument of circular, rather than linear, logic, or an inability to see how seemingly unrelated activities may be connected, and how seemingly related activities may be disconnected.

Poorly executed schedules are typically discovered too late – when they are no longer serviceable due to being underdeveloped, or because they have not been maintained to reflect current status. A general contractor will invariably find himself having to retain a professional scheduler to re-baseline, or regenerate a project schedule that no longer serves its intended purpose.

Schedules become obsolete far too often, and resultantly see their demise in real-time. This is because contractors generate baselines that remain static, and are not continually reworked to reflect changes and developments in the sequence of operations that occur over the prosecution of a project. Contractors fail to keep schedules current by not involving the scheduler in the daily operations and flow of information loops that affect the schedule. In doing so, they preclude their responsibility to contract compliance, as well as their ability to mount a delay claim.

“Accordingly, contractors receive 10 cents on the $1 for their compensable delay claims.

Invariably, reworked schedules may involve mitigation, or planning to minimize delay impacts in the critical path(s). These reworks require close interface between the scheduler, project management, and vendors and trades affected by changes. Too often, these interfaces never take place, or if they do, result in half-cocked efforts lacking reflection of complete scopes of work. That is all to the chagrin of the scheduler trying to do his job.

For example, contractors frequently present foreshortened mitigation schedules that require extra resources, or acceleration or compression, sequences that have not been ratified by their respective vendors. These schedules look fine on paper, but are not considered thorough without complete buy-in from all parties.

Far more efficient is the scheduler who isn’t reliant on third-party information, and who takes the initiative to be proactive and determine what input is lacking or needs to be refined. That means putting on the hard hat and getting intimately familiar with the mechanizations of field installations and administrative paperwork. This enhanced role of the scheduler will represent the contractor’s best effort provided the scheduler has the ability and insight to be a dynamic (updates) as opposed to a static (one-off-baseline ), play caller.

The trouble is, there simply aren’t enough good schedulers who came up through the ranks and rites of passage of a seasoned professional. The industry itself is mostly to blame for this conundrum. The solution partially lies in changing the way companies cultivate their resources, from little or not at all, to more robust and substantial programs of learning and practice. The challenge lies in reversing the trend of underfinancing of training programs and technophobia that the building industry is notorious for.

A seasoned field mechanic is in a far better position to be cultivated as a scheduler owing to hands-on skills and knowledge most schedulers will never have, yet these individuals are the exception. Most will tell you they are afraid of learning CPM – that it is too difficult and confusing. However, it only seems that way until it is learned. Once learned, most of the scheduling operations will become second nature, and what was once thought elusive and impenetrable, is suddenly accessible and serviceable.