BIM Coordination technology is Driving Complex Building into High-gear

In the past, I’ve been a bit skeptical as regards adoption rates of BIM Coordination technology among builders. Fake news that overstated data was partially what motivated me. Since then, I’ve seen and had more exposure to how BIM Coordination technology is increasingly used by builders, and at greater depth, in ways that better control time and budget than conventional means. It would be interesting to peruse some reliable data on current adoption rates. Notwithstanding the absence of such studies, I can report from personal experience.

As I have said, larger scale projects will lend themselves better to BIM Coordination technology than will smaller enterprises, as the technology still requires a substantial investment in the product, training, deployment, and management for which small scale lacks sufficient resources. The resources required for adoption are still out of reach for most specialty contractors, save for those who want to compete on the larger scale projects.

Five years ago I wrote “BIM Technology is indeed an impressive technology that no doubt holds brilliant promise for the future of some component of the AEC community. But trying to find out just how fast it is catching on in the building industry is an elusive undertaking.” In today’s landscape, I have learned just how beneficial BIM can be for builders, and even seeing adoption among specialty contractors.

Many project managers have or engage in BIM technology (as opposed to design) training that augments their daily arsenal of tools they use to coordinate the more complex and sophisticated projects that are under their stewardship. Recent entry-level staff are trained in BIM technology as part of their education – new curriculums are created. The added value of ‘bright young things’ to the industry cannot be overestimated – they fit a vital support role to their project managers and specialty trades, although they will still need years of site experience to comprehend means and methods in action.

BIM technology for project managers will include macro and micro-scale coordination of scopes of work from out of the ground through fit-out. Project managers have the advantage of means and methods knowledge that most designers do not, for lack of site and practical experience: their only notion of parts fitting together are on paper or screen. More experienced designers – and especially engineers, are expected to have working knowledge of means and methods, for example, a structural engineer often provides a Sequence of Operations that informs means and methods in which he or she is literate.

“To some extent, much coordination and clash detection is to be negotiated by the designer in the construction document phase, however, this is not always – some would say ‘seldom’ – the case.

A new building will be easier to design-coordinate than new construction over existing, given the constraints and unpredictability of unforeseen conditions in existing work. The level of coordination of any construction is contingent on the ability and investment the designer has made. Not infrequently, a lot of design coordination left to the specialty trades is deferred design responsibilities, or design errors and omissions, for which designers carry (E&O) insurance. In some cases, a contractor may be within his rights to ask for a design fee.

The more complex the coordination effort, the more the builder will involve his project managers and specialty trades. Contractors provide resources for BIM Coordination technology in their general conditions budget. Many project teams with aggressive schedules struggle to timely execute coordination, which can result in delay, the ownership of which is always hotly contested. Therein the incentive to launch BIM Coordination technology for a given project and organization as a mitigation strategy.

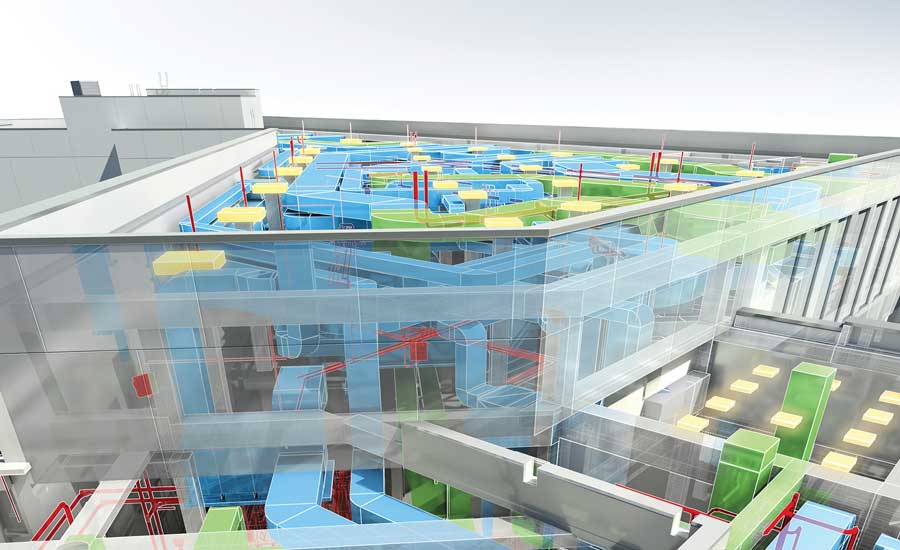

Both new and retrofit work requires coordination of structural, as well as MEP programs by the builder and his specialty trades. Traditionally, the mechanical contractor will act as captain, using the designer’s architectural drawings at .375/1’ scale as backgrounds to plot his duct and piping shop-drawings, and then overlay shop-drawings prepared by partner trades electrical, plumbing, and fire suppression. The shop-drawings of all trades will have been approved by the design team before MEP coordination modeling, which generally does not require design team review. Once the coordinated MEP drawings are completed over the architectural backgrounds, dimensioning and fabrication may begin.

Another breaking development I have also changed my outlook on is the integration of scheduling layers into BIM models (4D BIM). Five-years ago 4D BIM was a nascent technology, but cutting-edge engineers and designers are now beginning to avail themselves of the benefits, which include forward pass evolutions of construction elements according to scheduling time constraints. These models are also of extreme value to ownership, as well, giving them clarity where they lack coherent vision.

4D BIM technology is available from scheduling platforms, such as AutoDesk’s Assemble, which is tailored to ‘talk’ with P6: the engineer can input select activities directly into his BIM model to create a 4D BIM simulation that is amply sufficient to purpose, building and displaying timelined layers in real time. Ultimately, the 4D BIM model can be output into AR and VR studios.

BIM empowers contractors to optimize their coordination by creating models early in the process and with more control. Early coordination has the benefits of improving constructability analysis, reducing design errors and omissions, detecting program conflict, minimizing review cycles and change orders, and obviating costly EOTs (delays), all of which translates to diminished risk and maximum ROI in builders’s investments, and a win/win outcome for job teams.