Artificial Intelligence disruption of the AE (architecture and engineering) industries is closer than many of us think.

When we talk about any kind of industry disruption, a lot of people become uneasy, for fear their services may no longer be required. And so it is with artificial intelligence disruption in the AE industries. Real AI design systems and tools, like AutoDesk’s Autoroute, and BSP’s GenMEP, are already changing the clash-detection battlefield in a substantial way. Google’s Tango device ships preloaded with area-mapping and depth-sensor capabilities.

While obsolescence may be a nigh reality for a great many, there will also be abundant opportunity created to support the new technology. In any scenario, Artificial Intelligence disruption will never be a zero-sum equation: human intuition and reason are still intrinsic to the process. Expectations must be that the construction industry will play catch-up ball to AI innovation, in its characteristic technophobic way; only those with their heads out of the sand will avail themselves.

Artificial Intelligence Disruption is Already at hand in other industries

The AI market is expected to reach USD$70B, by 2020. Too large to be ignored, it has already impacted global growth in the self-driving car and IoT markets. AI is already being deployed to other design applications such as a

Home Page Generator

Mimetic video

AI platforms like the Grid can build your website for you, when you’re too lazy to do it, or simply don’t know the ropes

*mimetic photography and video are author’s terms

AI designs websites, why not structures?

There is no longer an answer to ‘why not artificial intelligence disruption?’ Low production, and untimeliness of design deliverables pervade and negatively affect the building industry down the line, with specialty contractors bearing the brunt. AI proponents have their own bucket-list:

This is a story of a beautiful future, but we should remember the limits of algorithms — they’re built on rules defined by humans, even if the rules are being supercharged now with machine learning. The power of the designer is that they can make and break rules; so, in a year from now, we might define “beautiful” as something totally different. Our industry has both high and low-skilled designers, and it will be easy for algorithms to replace the latter. However, those who can follow and break rules when necessary will find magical new tools and possibilities.

Moreover, digital products are getting more and more complex: We need to support more platforms, tweak usage scenarios for more user segments, and hypothesize more. As Frog’s Harry West says, human-centered design has expanded from the design of objects (industrial design) to the design of experiences (encompassing interaction design, visual design and the design of spaces).

The next step will be the design of system behavior: the design of the algorithms that determine the behavior of automated or intelligent systems. Rather than hire more and more designers, offload routine tasks to a computer. Let it play with the fonts

- First-generation systems mimic analogue tools with digital means.

- The second generation is assisted creation systems, where humans and machines negotiate the creative process through tight action-feedback loops.

- The third generation is assisted creation systems 3.0, which negotiate the creative process in fine-grained conversations, augment creative capabilities and accelerate the acquisition of skills from novice to expert. (Algorithm-Driven Design: How Artificial Intelligence Is Changing, Design, SmashMagazine, January, 2017)

Anatomy of an AI Design

There’s no longer any compelling reason for AutoCadd drafters to endlessly design mundane structures, such as warehouses, courthouses, correctional facilities, movie theaters, shopping malls, switch-farms, leisure sports-complexes, outlet stores, dormitories, public-housing, self-storage, and other buildings that have redundant designs that can be in large part be standardized. Such design programs comprise a considerable unnecessary expense and drag on the industry, and contribute to negative production in the construction sector.

Design deficiencies and errors and omission drive disruptions and delays more than any other factor. AI would in large part obviate human error with clash-free autorouting tools already in use.

What’s more, because of a lack of standardization, it seems every other designer seems to have to reinvent the wheel, despite garden-variety program criteria, perhaps as a make-work measure. To paraphrase: it takes far too long to develop complex deliverables than it should, which makes the industries ripe for artificial intelligence disruption. One of the reasons is the inability to incorporate design changes efficiently.

The less standardization there is for mundane design assignments, the more that can go wrong, and the more costly. When designs are standardized, errors and omissions can be treated globally, as opposed to epidemically. That is just one advantage of parametric modeling.

There are clearly many building sectors that will lag in AI assisted design, for their complexity that defies design standardization: oil and gas, petrochemical, industrial, nuclear, plant work. Indeed, when aesthetics come into play whole new sets of generative design come into context. Some sectors will be impacted less than others, or rather, AI disruption means less dependency on operators, depending on the degree of standardization in that sector.

The Generative Process

- AE loads design parameters, materials, into a generative design systems such as Dreamcatcher

- BIM uses algorithms and reasoning to generate design options, as well as performance analysis for each of the designs

- AE modifies goals and constraints for AI to come up with relevant solutions

- AI learns algorithms and creates MR immersion options, and finally, 3D printed models to finalize the design process

Wegner’s Chair, Algorithmically Optimized

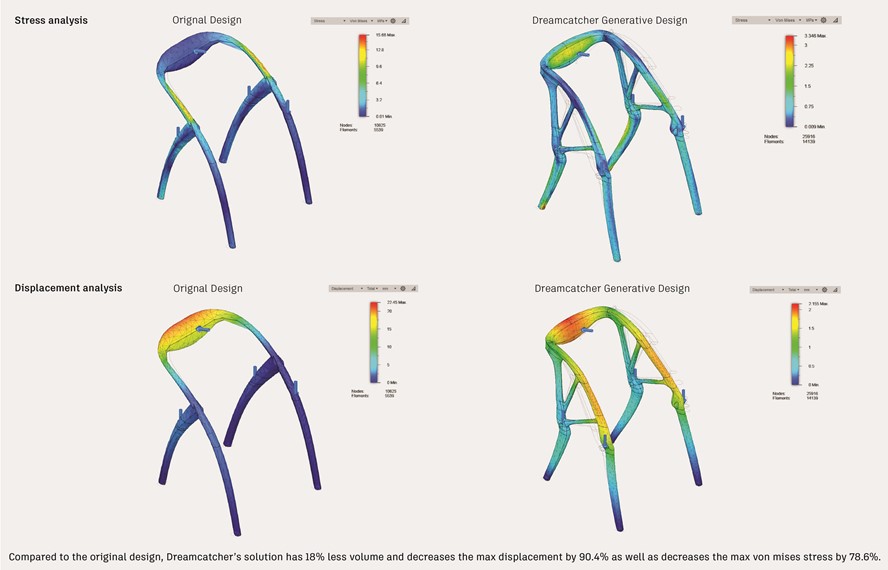

Earlier this year, Autodesk tasked AI with re-engineering Wegner’s 1950 classic Chair JH503, the Round Chair, and the results were quite profound.

Optimizations

- Reduce cost

- Reduce development time

- Minimize material consumption, and product weight, without affecting styling and comfortability.

Here’s what AI came up with:

Compared to the seed geometry, the Elbo Chair has 18% less volume; decreases max displacement by 90%; and decreases the max von Mises stress by 79% (and above, AutoDesk, 2017)

The algorithmically optimized chair

Stay tuned! Next post AI BIMs a project on its own!