Artificial Intelligence has both unlimited potential and limitations in the process of developing complex CPM construction schedules

“Good design has inspiration to it… if you have that vision you can encode it and parameterize it and explore it further. Now we have a rich flora of options.” (Autodesk, 4)

CPM schedulers, planners, oversight wizards, and Clueless Emperor CFOs and public capital construction directors, have been under servicing the building industry to alarming levels of incompetence ever since a time before most of us can recall. By many measures, less than one-quarter of all work set in place in a given year meets budget or targeted deadline. Add to this torpor negative productivity rates, and you have the perfect breeding ground for disruption, and that disruption could be artificial intelligence.

“Can the building industry jump the shark from Flintstones to Jetsons?

In the last century, CPM scheduling was traditionally performed by trained personnel. At some period in the latter part of the century, the supply as well as the demand of trained professionals became decimated, and the industry was deprecated to a considerable dearth of scheduler talent, or what we have to work with today. The reasons for this are somewhat beyond the scope of this present discussion.

“Epidemic poor project control practices and management have enfeebled the industry when they should empower it.

Some two third of today’s building industry now use project managers as their de facto CPM schedulers. Coincidentally, between 60 -75% of all work in place fails to make the deadlines these schedules target, though one can hardly saddle the scheduler with all the blame. By combining a project manager and (very part-time) scheduler into one job description contractors have been doubling down on this general conditions, which they bill ownership for – a contract requirement by giving it short shrift or ignoring it altogether.

That’s no small consideration to stakeholders and owners who pay for the service and simply don’t get it. They need dead-nuts cost loading, EVAs, and projections, to manage their assets efficiently and with quality information. If a CPM schedule is not properly cost loaded, it will not be useful as a cash-flow managing tool. Moreover, a cost-loaded CPM schedule is never sufficient as the sole means of control: robust analysis and forensic programs and risk-assessments are needed for executive level controls.

The current crop of CPM schedulers

The reasons why trained CPM schedulers don’t do more than one-quarter of all CPM scheduling is because it is generally considered by many GCs as discretionary spending – read: “that which can be forgone without losing much skin: the ability to make a delay claim, should the time come, is one downside of not keeping track, the other is a lack of accountability. Contractors’ ROI on claims is so parsimonious that the necessity of tracking a schedule seems like a waste of time.

“AE industry will get the memo but will The Town of Bedrock?

There are a fair amount of PSP certificate holders, as there are technical scheduling wizards, but most of these have no field or even industry experience, and as such often have no view to assemblies, or an intuition of basic duration and sequence of operations. In other words, they are limited in their capacity to help resequence a given project delivery. Some of the best schedulers I know are veterans of the industry with no certifications. There are few signs of a new crop of CPM schedulers arriving any time soon, as not many would consider it as an avocation.

PrimaDonna organizations issuing the scheduling certificates seem fairly clueless – still using testing material that appears to be drawn from the 1950’s, #2 pencils included. It might strike some as quaint – the notion of taking a two-hundred question test with out a computer or software. Indeed, CPM scheduler certificates (PSP) are not well represented or particularly held in high regard in the industry either, making up the smallest group of certificate holders. The issuing organizations also tend to thumb their noses at non-members in order to puff up their own constituency, making them poor choices for partners in development.

“I get a lot of basket-cases – takeovers, with hard-dates and constraints. These are merely glorified Day Runners, utterly devoid of project logic. All are rebaselined.

Typically, construction managers and larger general contractors are the employers of trained CPM schedulers because their level of oversight requires it, and because they have enough work to keep a scheduler on full-time payroll, which most everyone other than a consultancy does not. It’s easy for a CM who simply bills the owner for CPM reimbursable services, but for most others it is something they prefer not to do at all, and will relent only under considerable pressure..

Yet even CMs and large GC firms often require engineering degrees or certificates for schedulers that don’t really seem to impact their success rate. However; the consensus in this century is that any GC or CM finding a qualified scheduler at all should thank their lucky stars they found a qualified person at all. Specialty contractors – who comprise 75% of the industry, either don’t have a trained CPM scheduler, or simply don’t submit schedules at all. Accordingly, they are invariably poorly positioned, and lacking any leverage to make compensable disruption claims.

“To the layperson, a flat GANTT chart is no more accessible than it was in the 1950’s and just as resistant to their reasoning.

This distraction disempowers them from the ability to make compensable delay claims, and accordingly, the industry absorb those costs. But stakeholders also lose on delayed projects. They have to service high interest construction loans, tie-up bonding, extend carrying costs, and defer operating revenue. Indeed, stakeholders will seek to reacquire investments losses caused by delay with claims of their own.

CPM in its current manifestation as the unilateral means of managing risk has failed to demonstrate benefits

Since post WWII, CPM or critical path method, has been the default project delivery tracking system by which the construction industry forecasts and marks progress. Recently, CPM has been criticized for its inexactitude and other perceived shortcomings, in favor of alternate approaches that include CPM as only one of several methods of approach to time that include vigorous risk management. Despite new approaches, and lots of hype, few have failed to mainstream or make any noticeable improvement to project delivery.

Along Comes BIM

Recent developments in BIM platforms – specifically, 4D, 5D, 6D, and 7D are already poised for disrupting the project controls industry by displacing estimators and schedulers from the planning, R&D, D&D, and critical oversight processes. But the BIM industry is guilty of hyping itself to ridiculous proportions – specifically adoption rates. Let it be said, that if less than 10% of all work in place was “BIM driven” – a loosely defined term, that it cannot be considered disruptive. Tracking true AI rates of adoption will be equally elusive.

But that doesn’t mean BIM doesn’t work. In fact, quite the opposite is true. When BIM is used properly, projects can realize up to 25% savings on their bottom line, and finish with float to spare: 16% (Dodge, 2017, 7) of users reported improved schedule. Surprisingly, 36% of the Dodge non-BIM users survey respondents reported negative experiences toward BIM – a not insubstantial sub-set.

4D, 5D, 6D, and 7D are nascent platforms, that will shape up as the BIM models they are based on become more sophisticated. Indeed, cost-loaded 4D BIM CPM schedule animated models are invariably inaccurate because they are not properly plotted based on resources and productivity rates, only estimated costs or durations, mostly from cost guide books, which are only able to issue average duration. These durations are plugged into 4-5D BIM interfaces to output simple renderings of time over the CADD layers.

“

Artificial Intelligence will be taught to to generate CPM schedules on its own, but who’s going to teach it the algorithms?

The shift to Artificial Intelligence project controls will be gradual, as the technology finds its bearings through adoption, and continued advancement and investment in the platforms. The degree of success is largely predicated on input from the building industry. The expectation is that once the value in Artificial Intelligence CPM scheduling can be demonstrated, stakeholders and owners will take notice, and demand it from their architects and engineers, who will incorporate it into their program, with or without input from CMs and GCs other than hard-dates. Therein lies a critical disconnect.

“Starchitects: get your BLOBs out of AI’s way and make way for optimized designs

One of the biggest encumbrances to industrial Artificial Intelligence adoption will be a lack of design standardization: if designs are not standardized, it will be that much harder to create algorithms for every instance of possible sequence of operations, as well as BIM 7D lifecycle modeling. Once AI BIM designs are standardized, the 4D-7D modules will fall into place after them. Naturally, there are entire groups of structures that don’t lend themselves well to AI BIM, and these will always prove resistant to standardizations.

“Artificial Intelligence design platform interoperability issues could force a Darwinian shakeout if marketshare doesn’t first.

This same tendency to seemingly reinvent the wheel with every new project creates an unnecessary drag on the AEC industries, and most recently the nuclear industry. As designs of mundane structures are substantially or wholly standardized a considerable positive impact can be expected from conception through project lifecycle, i.e., 4D-7D BIM. As AEs churn out endless one-off custom projects, so must estimators and schedulers continually prepare unique work product for each one. That is a practice that will have to be severely truncated.

Design standardizations would mean that Artificial Intelligence could

- Maintain design libraries that were easier to manage and access on a global scale

- Optimize algorithms into design criteria for entire groups of structures over a WAN

- Develop 4D and 5D BIM models from which to draw estimates and CPM schedules

- Make global program BIM changes and regenerated models

- Deliver benchmarks and performance metrics from a master database

- Launch 6D sustainability and 7D BIM lifecycle models

Fragmentation and customizations are the weak suit of Artificial Intelligence. Before AI can do its best work, it needs a basis of analysis. If a project is fairly unique and customized, AI won’t have a knowledge-base to draw from. The challenge is “abstracting design goals and parameters into quantifiable representations is the first level of abstraction that design optimization demands from users.” (Autodesk, 6)

At what point does Artificial Intelligence adoption become ‘disruptive’?

As AI gradually takes over more of the intuitive and cognitive processes, most CPM schedulers can be phased out, and their duties delegated to clerical level data-gathering personnel. I daresay most CPM schedulers will become obsolete in ten years time, save for those who have prized knowledge in highly specific and customized work, such as chemical, processing, manufacturing, processing, nuclear, hospitals and airports, that don’t lend themselves well to standardization or machine learning.

AI disruption in any industry is predicated on the success of the Generative Process

The AI Generative Process

- AE loads design parameters, materials, into a generative design platform, such as Dreamcatcher or Grasshopper

- AI BIM uses algorithms and reasoning to generate design options, as well as performance analysis for each of the designs

- AE modifies goals and constraints for AI to come up with relevant solutions

- AI learns algorithms and creates MR immersion options, and finally, 3D printed models to finalize the design process

AI will be able to design, estimate cost, and generate a CPM cost-loaded model for mundane projects, such as big-box retailers, factories, plants, schools, dormitories, affordable housing, prisons, and warehouses, because it can draw data from a vast library of typical or similar structures that can easily be standardized, in the cloud.

AI 4D BIM Automation

The failure of BIM to mainstream begs the question as to whether to blame the operators, the platforms, or both. The answer isn’t simple, but the solution lies in AI automated and semi-automated platforms, that will overtake current BIM platforms. AI 4D and 5D BIM will be markedly different than what’s available now, with a level of exactitude heretofore unachievable.

The degree of achievable automation is contingent on several criteria with semi-automated as the alternative:

- Degree of design standardization: many mundane structures can be AI designed in toto, or in part. BIM 4D CPM scheduling requires the 5D platform of cost, in order to calculate variable costs and rates of productivity.

- Available resources: optimized algorithms for particular program as they become available, that AI needs to populate its database with.

- Degree of customizations. For the sake of efficiency and economy, unnecessary customizations to mundane structures can be standardized, or based on a limited number of models that AI can render.

- Ability of AE and construction (C) industries to facilitate the integration of optimized algorithms into developmental level models

Optimized algorithms for AEs facilitate machine learned intelligence,

-or artificial intelligence, that can self-design, and model cost and time on its own, based on users’ parameters that are drawn from a universal database.

Contrasting with traditional design practices, optimized designs are computed parametrically and bred algorithmically. The numerous design alternatives that are produced are often represented by a multi-dimensional plot of solutions and might be coupled with a matrix of thumbnails of rendered designs (Autodesk, 2)

Figure 1, left. Sample Design Optioneering Results, from (Gerber et al 2012).

Optimizing Risk Positions

Figure 1 point-cloud map will look familiar to risk-assessors (RAs), as it will to any point-cloud modeler. RAs model risk with their Monte Carlo simulations using CPM schedules and risk registers; however, these schedules are invariably flawed, as they are not based on constrained resources and productivity rates. Yet RAs are vastly underutilized in the building industry, even for the largest capital projects lead by our most Clueless Emperors. Thus, the large majority of building projects are risk-managed exclusively from CPM timelines, i.e., sans risk assessment. If that were not so, it would be easier to model time, cost, and quality aspects directly from BIM.

Projects should be risk-managed, but the folks calling the shots often think a Risk management is a board game strategy. Using CPM + a lot of guesswork will never replace a proper RA. This means the folks invited to the risk-register meeting need to be the ones providing the input. It follows, that best practice dictates that the CPM schedule be created in tandem with the risk assessment, which was derived from a BIM model that was based on available resources and real productivity rates..

The introduction of a risk-optimized CPM baseline into the project BIM master model is a necessary step toward risk-mitigation. The data generated today from AE BIM efforts for the 4D BIM will invariably be poorly suited to risk modeling without critical input from the risk and project critical path resources. Rather, the risk-optimize baseline can either be created in tandem with design optimizations, or it can be backed into the BIM model post-design completion; however, this latter defeats the purpose of having risk-optimized foreknowledge in the planning phase.

Whose 4D BIM ?

Before we can discuss AI CPM scheduling, we must revert to the 3D BIM model that generates the parameters that will yield the data to build the schedule, and estimate the cost. Without these, AI has no data set to draw from. These models are by and large owned and used by AEs, who rarely integrate 4D or 5D BIM, and seldom partner with the project controls team in the way they need to.

Generous data sets for construction schedules are extant in cloud databases, categorized by project type, and benchmarked according to performance and logic integrity. Platforms such as Acumen Fuse compare any given uploaded timeline to all similar projects in the database and return a report of metrics, as well as industry benchmarks for project logic and likelihood of making deadline. This data could be part of the knowledgebase that AI BIM will use and reuse to design and schedule similar projects.

Much like a genome encodes a genotype, a parametric model and associated simulations encodes the expression of form and performance across any given set of parameters. The parameters tell the design story. (Autodesk, 8)

It is from this set of data that AI will derive variables in sequences of operations for complex activities based on nature, volume, and rate of production it finds there. For example, 5,000’ of copper water piping in an assisted living project would be done in a fraction of the time as the same amount of pipe in a medical laboratory based on factoring from as-built schedules and standardized models. From mean values degrees of difficulty can be weighted from less or more than average, and assigned a multiplier.

Project managers and CPM schedulers will be needed to assist AI, and maintain its knowledge-base using ATMS. or assumption based truth maintenance systems:

Assumption-Based Truth Maintenance Systems (ATMS) [DeKleer, 86] represent an Al technique that permits an experienced project manager to manipulate knowledge about the implications of choices in the objective-setting stage of a project. Moreover, ATMS techniques facilitate analysis of the effect of changing assumptions in multiple scenarios or “worlds.” By maintaining knowledge about which implications depend upon which assumptions, they permit a project team to explore and modify a host of interacting assumptions about a project and to infer the implications of each set of assumptions Rapidly (Levitt et al.,32)

When Levitt say “assumptions” and “multiple scenarios of ‘worlds’” he is referring to sets of 1,000 or more possibilities.

Kleer explains the advantage of an assumption based TMS in tandem with a justification based TMS as providing fertile ground for operators to explore their best options far more efficiently than ever before:

Unlike previous truth maintenance systems which were based on manipulating justifications, this truth maintenance system is, in addition, based on manipulating assumption sets. As a consequence it is possible to work effectively and efficiently with inconsistent information, context switching is free, and most backtracking (and all retraction) is avoided. These capabilities motivate a different kind of problem-solving architecture in which multiple potential solutions are explored simultaneously. This architecture is particularly well-suited for tasks where a reasonable fraction of the potential solutions must be explored.

Once parameters and optimizations have been set, AI BIM can compare multitudes of designs simultaneously. This potential represents exponentially higher build-model times that can significantly reduce design and development stages, while offering the maximum range of optimized choices. D&D program changes will be made on demand, in lieu of tedious and costly redesign work ups that drain the design budget.

Optimized design algorithms

Design parameters set by the AE team should be informed by project controls – estimating and scheduling. This is a divergence from traditional AE practice to design without any consideration of cost and time other than what they fathom or glean from a square-foot estimating guide:

“Design optimization tools are creation tools that use parametric modeling, performance simulation and mathematical optimization to systematically generate and evaluate design alternatives (IJAC)

– That’s great; but AEs designing without due consideration of cost and time parameters do not deliver a complete design package. This is because of a failure to involve project controls professionals in the process. For this reason, AEs current brand of 4D and 5D BIM product is invariably incomplete design; their colorful models no more than eye candy. Part of the problem is the classical disconnect and lack of trust between designers and builders. Another is the tacit assumption by many AEs that the construction industry in general is not sophisticated or educated enough to partner with them..

These design parameters are set by the AE team, which is to say that they maintain a hand in the process. Besides, they own the BIM and the models. The dilemma of putting AI to create generative design options as somehow depersonalizing the creative process is bunkum, because AEs will be the ones loading the parameters.

genomes and master files, are the symbolic description of the design problem. These files are the design story as told by the parameters. This type of documentation is a fundamental departure from the set of elevations and floor plans in traditional design. The obvious analogy, used by our participants, is that the master file is a genotype and the set of CAD drawings is a phenotype. One study participant cautioned us that there is “not a perfect translation of genotype to phenotype” implying that design optimization does not replace the expertise of the architects.(Autodesk, 7)

Nonetheless; the AE industry had a rather tepid and characteristically whiny response to design optimization output from a study: “the usability of the output is not there… even the visual examples are hard to digest for us, much less for the clients who don’t have the expertise.” (Autodesk, 8). Flager and Haymaker believe “poor user experience is due in part from a dearth of user experience research in the field of design optimization (Flager and Haymaker 2007).

Design and cost algorithms need to be robust enough in order for AI to offer as many solutions as possible for cost and schedule, as for quality. The more standardized and populated the knowledge-base becomes, the sooner the potential for disruptive take-over becomes imminent. This will not happen without continual industry input from seasoned estimators, schedulers, and project managers.

It must be said that design optimization is not limited to the building and construction industries – far be from it; it is merely a means of conveying an abstraction into a three dimensional model.

“Revit [a CAD tool] is rational. When you’re working in Revit, your goal is set: I’m designing a building. I’m producing construction documents. In Grasshopper [a design optimization tool] there is no prescribed approach nor outcome. I can design a tree or a car.”

The following are examples of building design optimization parameters:

Develop conceptual or theoretical areas and volumes of space to optimal use and performance based solely on a given program or use: i.e., retail, institutional, multi-housing, hospital, etc.

- Design structures based on footprint, zoning, usage, and code requirements

- Minimize loss of GSF and head-room to dead or wasted space

- Where clearance is a concern yield/relocate to conflict program

As regards generative design

“Engineering and architectural design are inherently generative disciplines. The set of design algorithmically computed alternatives for any given real-world design task is vast. Flager et al. calculate that for the one room, steel-frame building used in their energy and structural optimization study there were 55,106 possible solutions (Flager et al. 2009).

there will be abundant options, perhaps too many.

- Incorporate specifications that are LEED compliant

-

- Model Indoor Air Quality (IAQ) scenarios

- Minimize waste, maximize post-consumer recyclables

- Model Indoor lighting and dimming scenarios

- Project energy, maintenance, and repair costs over project lifecycle

- Model cost based on Bronze/Silver/Gold/Platinum criteria

- Develop multiple cost, schedule, and risk scenarios, and weigh them against discretionary budgets for 200,000 SF x 10 stories

-

- A l00 unit luxury condominium

- A 150 unit middle income

- A 200 unit affordable housing

- Optimize material and exposure for heat gain/loss

-

- Specify glazing system according to desired thermal outcome

- Determine BTU-optimized performance for a building and its HVAC equipment and components according to use.

- Develop louvered convective curtain wall systems that reduce AC load

- Specify roof systems for minimum irradiation according to climate data

- Consider substrate, soil, and other environmental data into design program

-

- Develop footing and foundation layout to minimal excavation requirement

- Locate piles according to optimal placements

- Minimize overburden and superfluous rock removal

- Model options of cut-and-cover v. TBM tunnel and shaft-work

- Incorporate pediatric-friendly environments

-

- Draw from a paint and wallpaper pallet of warm hues that make kids feel safe

- Specify and detail based on juvenile equipment and furnishing guidelines

- Require specialty electrical outlet blanks

- Design for assisted living

-

- Incorporate extra safety and warning design elements

- Include ramps, auto-opening doors, wheelchair wall bumper

- Specify ADA hardware and accessories

- Comply entire structures

-

- Design for varying classes of fire protection

- Indicate security doors, frames, and hardware for varying levels of security

- Specify partition and roof insulation according to code and climate data

- Engineer material for loads based on use

Where to begin the generative process?: in the knowledgebase.

AI BIM design optimization is not intended to displace designers but to facilitate them:

Designers using design optimization tools combine ideas through the algorithmic generation of design alternatives, they experiment through adjusting design parameters, and they explore through examining data visualizations of solution sets. Optimization tools do not simply automate idea generation. They support the creative process of idea generation, exploration and refinement. (Autodesk, 2014)

Once AI generates a BIM model, it can render 4D and 5D BIM models far more accessible to stakeholders that could well obviate the need for AE CPM schedulers and their GANTT charts, which they can’t seem to decipher anyway. These models would be far different than the animated models. Instead of the model being a product of BIM, it will build with the use of parametrics uploaded to the platform by professional project controls personnel.

AI BIM CPM Schedule Builds

If we consider the overview of CPM schedule structures we discover some underlying principles that many have in common, and lend themselves well to standardization:

- There are a considerable number of repetitive submittal, review, approval, and fabrication and deliver activities in the preconstruction window of most any build-out. These require little intuition from AI and are easiest to standardize, as trained CPM schedulers know how to do.

- Activity durations are a factor of volume and rate of production, as opposed to intuition. These are derived from the estimate, which is taken from the project drawings.The database for every type of construction will require years of proper cost and resource loading, and frequent updating of same by professional estimators and schedulers.

- A consistent and rigid order of precedence exists between many assemblies, for example, ‘high-rise mixed-use out of the ground:’ steel-Q-deck-concrete-pour-mat slab-foundation, roof system-interior fit-out, that lend themselves substantially well to standardized sequence of operations, or at least standardized order of precedence, e.g. shower body-substrate-tile-controls-trim, that cannot be broken.

- CPM schedules are frequently used as the sole basis for risk management. AI would incorporate risk factors and multiple float-path management on a regular basis, changing the way risk is monitored. Risk registers would be a semi-automated process, as they are today, with RA professionals loading the risk profiles in risk-workshops. Some of these profiles can be standardized, as well.

The promise of AI in BIM 4D CPM implementation would seem to be constrained by the number of variable production rates for the same or similar activity, as it is in most CPM scheduling platforms. This is addressed in Aziz, Hafez, Ragab and Abdul-Magd discussion of their Smart Critical Path Method System software SCPMS and the multi-objective algorithms’ it utilizes. The software is designed to optimize or strike a balance of time, resources, and quality.

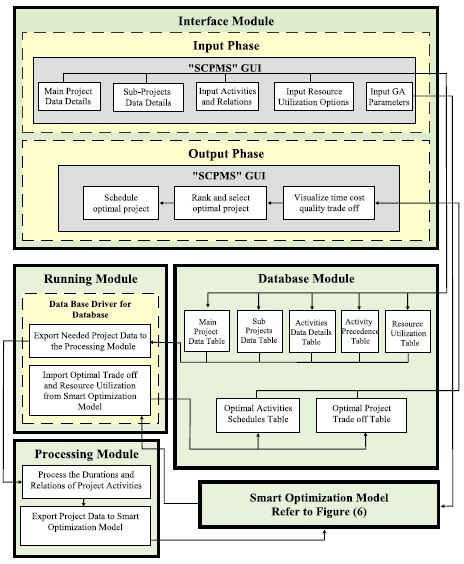

SCPMS’’ was developed in four main tasks that led to the development of: (1) database module to store the project data details, project activities details, activities relations, activities resource utilization options and genetic algorithm parameters; (2) running module to provide calculations with a seamless integration of database module with user interface module, processing module and the smart optimization model; (3) processing module was designed to perform all calculations and was developed to enable the integration of the database module with smart optimization model; and (4) user interface module to facilitate the input of project data and genetic algorithm parameters, as well as the visualization and ranking of the obtained optimal solutions (Hafez, etal., 16)

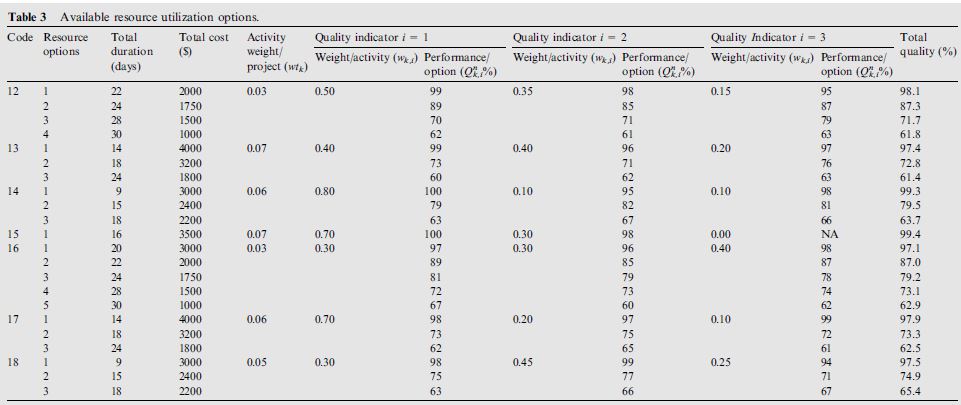

A case study by Hafez, et al., yielded the following optimization table, which shows the trade offs between time, cost, and quality based on weighted activities

The data exchange necessary to generate a smart optimization model for SCPMS models are

(1) an input stage that facilitates the input of project data details, project activities, activities relationships, activities importance weights, available resource utilization options, and algorithm parameters; and (2) an output stage that allows the user to rank and visualize the optimal project scheduling solutions and optimal activity resource utilization options obtained by smart optimization model (Hafez, et al., 14)

The SCMPS is designed to develop and maintain a database of solutions and outcomes. The nine inputs for the SCMPS table are:

(1) project data details table; (2) project holidays data table; (3) project exception data table; (4) project activities table; (5) successors relationships between activities table; (6) available resource utilization options for each activity table; (7) quality importance weight for each activity table; (8) optimal activities schedules and optimal resource utilization option for each activity table; and (9) optimal project time, cost and quality tradeoff (Hafez et al., 9)

There are four distinct modules SCPMS needs for implementation

(1) database module to facilitate the storage and retrieval of construction scheduling, resource utilization, and optimal tradeoff data;

(2) running module to provide a seamless integration of the project database with processing module and smart optimization model and responsible for all calculations runs;

(3) processing module to do all calculations;

(4) user interface module (figure 2) to facilitate the input of project data and the visualization of the three-dimensional time-cost-quality tradeoff generated by the system (Hafez et al. 9)

Figure 2, SCPMS modules (Hafez, et al.)

AI BIM will never be a zero-sum equation where the robots run riot as “optimization tools do not simply automate idea generation. They support the creative process of idea generation, exploration and refinement.” (Autodesk, 2). AI BIM will require operators and programmers to teach it how to assemble proper WBSs for tens of thousands of options that should keep BIM operators busy for years. Although, in lieu of CPM schedules being ends in themselves, centralized and standardized optimizations will be locked into the knowledgebase for ready retrieval.

AI CPM scheduling will be implausible without proper integration of robust initial and continual optimized risk assessments. This requires critical interaction and sharing of BIM models between AEs, RAs, the building and project controls industry, stakeholders, and Clueless Emperors, not exactly great den mates. Of course, none of this is possible without AI hardware and software platform development. If AE are the only ones maintaining 4D BIM schedules, than we are in for a long Stone Age.

Works Cited

Hafez, Sherif Mohamed, Aziz, Fayek, and Yasser Ragab Abuel-Magd. “Smart Optimization for Mega Construction Projects Using Artificial Intelligence.” Alexandria Engineering Journal 53.3 (2014): 591-606. Print.

“The Business Value of BIM for Infrastructure 2017.” Www.construction.com. 17 May 2017. Web. 02 June 2017.

Levitt, Raymond E., John C. Kunz, and Nabil A. Kartam. “Using Artificial Intelligence Techniques for Automated Planning and Scheduling.” ISARC Proceedings. IAARC, 01 Jan. 1987. Web. 02 June 2017.

“Parameters Tell the Design Story: Ideation and Abstraction in Design Optimization.” Autodesk Research. Web. 31 May 2017.

“Parametric Design and Structural Optimisation for Early Design Exploration.” International Journal of Architectural Computing. Web. 31 May 2017.

“An Assumption-based TMS.” An Assumption-based TMS – ScienceDirect. Web. 02 June 2017.

GERBER, D. J., LIN, S.-H., PAN, B. AND SOLMAZ, A. S. 2012. “Design optioneering: multi-disciplinary design optimization through parameterization, domain integration and automation of a genetic algorithm.” In Proc. Symposium on Simulation for Architecture and Urban Design, Society for Computer Simulation International.

FLAGER F, WELLE B, BANSAL P, SOREMEKUN G, HAYMAKER J. 2009. Multidisciplinary process integration and design optimization of a classroom building. Journal of Information Technology in Construction, Vol. 14. 595-612.