5D Scheduling Could Be a Game Changer for Contractors’ Payment Strategies

Historically, getting paid on time is one of the biggest challenges that building contractors face. Thus, any vehicle that could speed up the process deserves their attention, as cash-flow is fundamental to their survival. This post details how the introduction of 5D scheduling technology into the building and construction industries could be a game changer for contractors who struggle to quantify work-in-place and ensure receive prompt payment.

In theory, and in most any boilerplate specifications, a construction schedule would be cost-loaded, and progress tracked in updates in order to accurately quantify work-in-place that could be transposed to payment applications. CPM schedules and payment applications would be in lockstep. In practice, this is a virtually unheard of process that is instead done with means and methods that have low levels of exactitude, and simply aren’t integrated into a schedule.

Despite the requirement of cost-loaded schedules, most contractors either eschew them altogether, or bundle by large area or scopes of work: for many contractors, it’s a challenge to even generate a critical path schedule with the right project logic, much less cost loading. Thus cost-loaded schedules are mostly intended to fulfill requirements than they are to be utilized as a document integral to the billing process: few contractors can generate a payment application from a progress schedule – a separate spreadsheet must be created – hence the term ‘double-entry’ accounting: cost-loading is a bit of an oxymoron owing to the knee-jerk approach of double-entry bookkeeping.

Given the rate of contractors who don’t cost-track, owners tolerate this oversight – albeit at the cost of delayed payments to contractors – this scenario places all the cash-flow leverage with ownership, leaving the contractor to scramble to get paid. As trades and vendors must also wait for payment it’s no wonder schedules begin to deprecate. Unfortunately, untimely payment seldom qualifies or can be represented as a schedule impact because the process from pencil-req to actual payment is one in which the contractor continually resubmits.

“Cost-loading is a bit of an oxymoron owing to the knee-jerk approach of double-entry bookkeeping.

Part of the challenge of cost-loading a schedule and using it as a tool to develop payment applications is that the most popular scheduling software doesn’t offer sufficient modules to do so. More difficulties arise when duration is not calculated according to real productivity rates, or physical completion percentage is conflated with duration completion percentage. Finally, the inability of contractors to accurately project remaining physical work or duration virtually guarantees rejection of their payment applications.

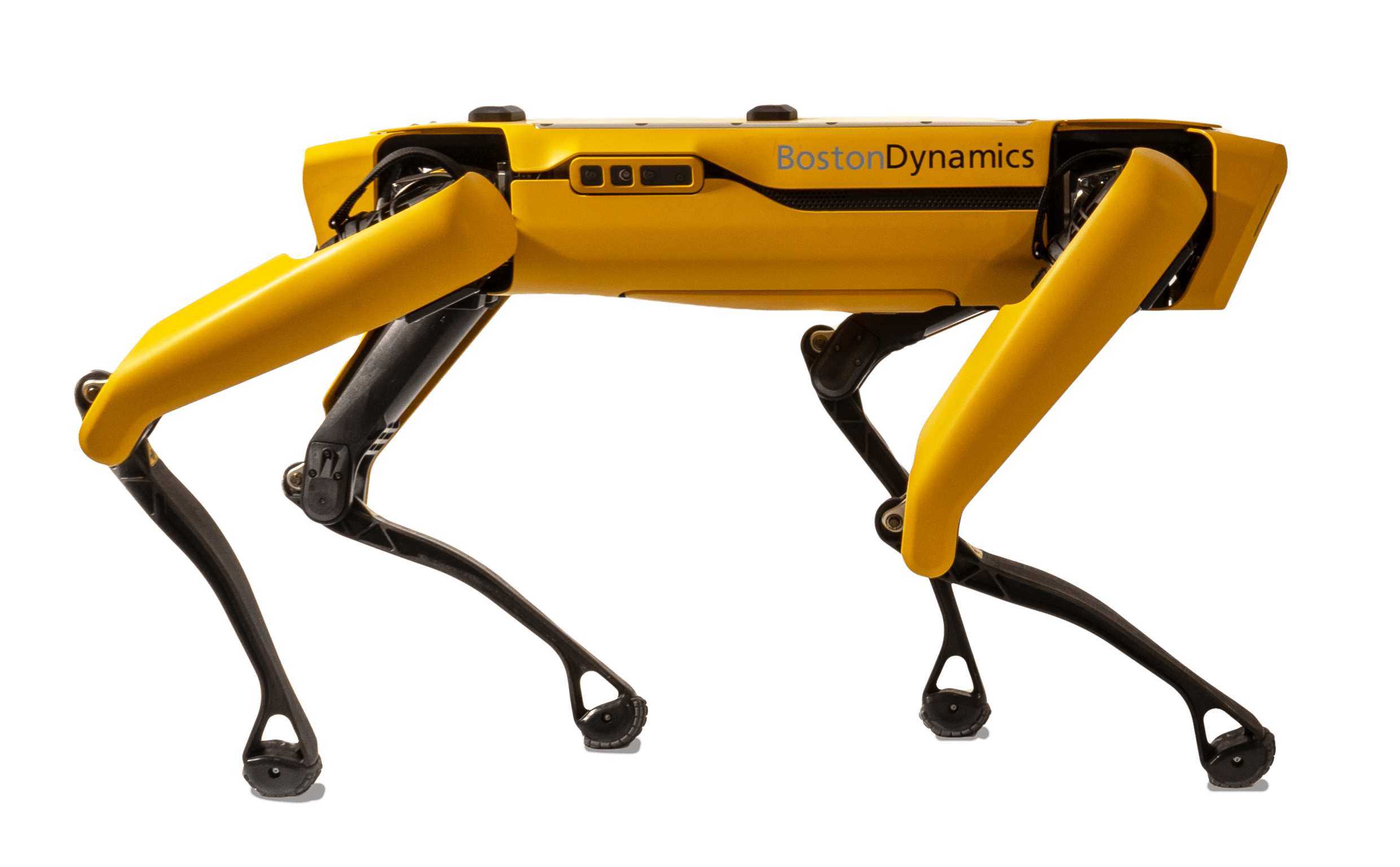

5D scheduling is a nascent technology where a 3D or BIM model is integrated into the schedule module to quickly and accurately capture work-in-place, and thereby speed up contractor payment processes. Groundbreaking tools include an autonomous quadruped spot robot armed with a LIDAR scanner that roams project sites and uploads images hi-res scans to an RGB (colored) point cloud – a process known as photogrammetry – where new images are compared with previous images in order to track progress.

5D scheduling systems use technology known as SLAM, or simultaneous localization and 3D mapping, the same one used for autonomous vehicles. Heretofore, a worker with a camera and clipboard would roam the site and manually record and document progress – a tedious process that invariably strings out contractors’ payment for 90 days or longer. By the time a project is updated for progress, much of the early noted work has already advanced well beyond the last recorded work. 5D scheduling is intended to truncate the process of recording and processing progress and issuing more accurate work-in-place values, thereby reducing approval windows. Developers of the technology seek to accelerate the process such that payments to be processed in less than one-week.

At present the manufacturer of the mobile mapping capture hardware, Kaarta states an accuracy rate of 50-60% accurate, which is still short of a 90% target. Capture rates vary according to the project: a simple cast in place core can easily be mapped, whereas complex MEP installations will take substantially longer. Kaarta Engine, advanced 3D mapping and localization algorithms, is at the center of the process.

Kaarta’s equipment and software is paired with Boston Dynamics sensor armed robots that are programmed to capture conditions and upload them to a point cloud. The platform is in the beta stage of launching, currently deployed on a pilot project, in Redwood, CA. However, the robots are already deployed in a number of industries, including O&G, mining, utilities, healthcare, and others, thus there is already strong support for the integration of new platforms.

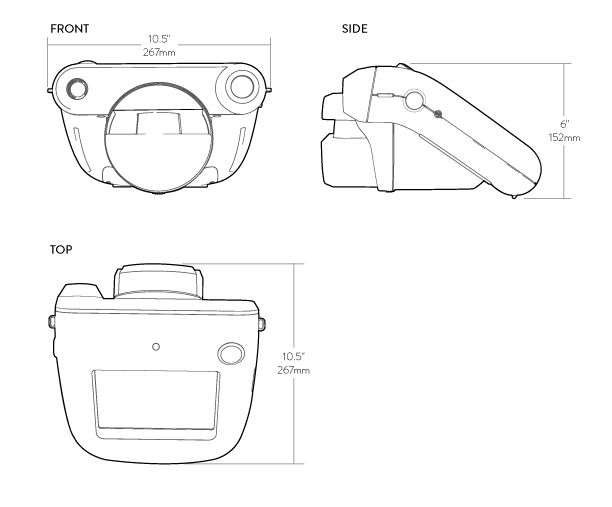

Kaarta’s ‘Stencil’ mapping instruments can be operated remotely, empowering the user with real time feedback and output to Kaarta’s touch-screen interfaces. The equipment boasts a range of 100m. They can be hand held, or vehicle or drone mounted, an ability that trupms traditional terrestrial bound systems. The technology is intended to replace older mobile mapping systems (MMS) by offering more efficiency and a less expensive price-tag. The device can be seen at work in the following video:

Although a person can also traverse a construction site armed with the same technology, alternatively several robots can be deployed at once, making 5D scheduling exponentially faster than old analog means and methods: each Kaarta Contour device can scan as much as 110,000 SF in about 2.5 hours. The system provides feedback in the form of ‘confidence levels’ of the scan model’s fidelity of the scan data.

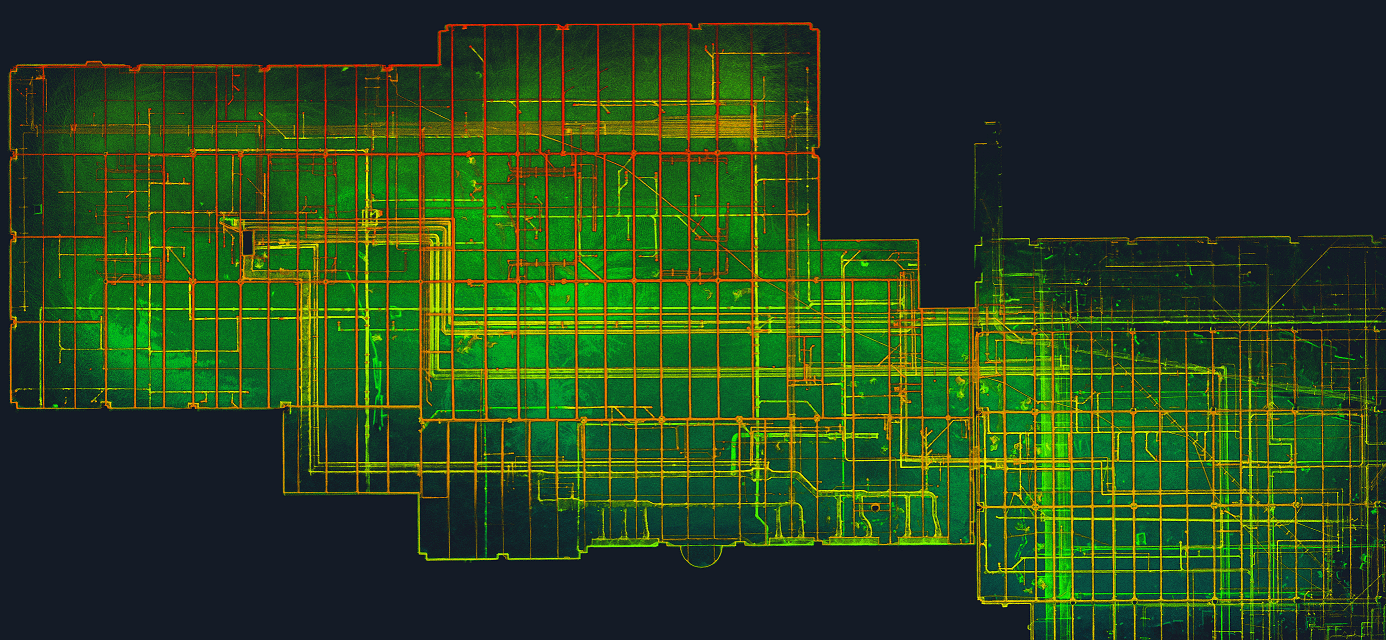

Consider the LIDAR scan below of a hospital crawlspace using Kaarta’s equipment mounted on top of an autonomous buggy:

An inspector with a LIDAR based scanner is far more accurate than without. Progress assessments without such measuring tools are merely estimates, often done with no measuring instrument. In this sense, they are subjective and subject to be challenged for their veracity by ownership, if for no other reason than to string along the payment application process.

The Contour Spec Sheet

Boston Dynamic’s robots can climb stairs, open doors, and easily navigate CAZs, HAZMAT areas, confined conditions, extreme temperatures, and rain and snow. The robot is crash proof, and can right itself in the event of a fall. The robots can be deployed during work hours, or during downtime. The LIDAR technology also provides an exponentially higher exactitude than traditional methods for calculating or scanning quantities of work-in-place that have a high margin or error.

Kaarta’s concept of mapping work-in-place arose as an application of quality control: verification of installations for compliance of design documents. The use of the data as a tool to track and valuate progress with 5D scheduling technology wasn’t the original intent, nor was it an afterthought. One Spot robot has a price tag of $74,900. That is the base cost without Kaarta’s equipment and software.

It remains to be seen if 5D scheduling technology can yield a fruitful ROI for contractors. If it can, then it’s merely a question of the rate of technology adoption, in which the building industry ranks dead-last. Such antiquarian attitudes would presumably have to reorient one-hundred-eighty degrees before they could be used to their full advantage. The hope and expectation is that the largest and most risky projects will be the first to avail themselves of the technology, making impactful progress to a heretofore tedious and inexacting science.