Will Project Estimators & Schedulers be Supplanted by AI-centric Platforms?

The short answer is – many project controls “professionals” will not be missed, but more talented professionals should see an increase in necessity and relevance to the merging of project controls into AI-centric project controls. This disruption would denote both intervention to traditional organizational structures, and innovation in AI driven megaproject delivery.

AI-centric (Mega) Project Controls

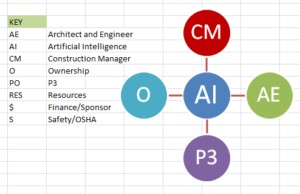

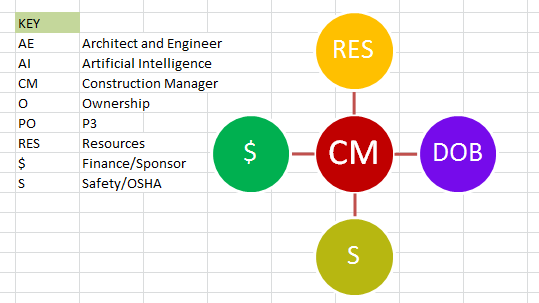

‘AI-centric MegaProject delivery’ is an AI-driven hub and spoke network, driven and guided by AI-centric project controls – estimating and scheduling – or, as any industry professional would put it: time and budget. Time and budget is governed by the prevailing rubrics for project delivery.

“Without the hub and spokes, there is no wheel. That’s how megaprojects roll.

Despite the zen simplicity of ‘time + budget,’ venture capitalists, executive administrators, Ivy League CFOs, MBA appointees, and politico bureaucrats who control the fate of megaprojects prefer to obfuscate, rather than illuminate, bifurcate and equivocate, facts; as far away from simple answers as possible. This practice is known as ‘strategic misrepresentation,’ or more familarly: ‘bull-shit,’ and is well documented in Flyvbjerg, et al.

“Megaprojects of the past seem to wallow in the complacency of their own clandestine organization that was seldom held to account.

Invariably, megaproject budget and time constraints become so distended of their original design and purpose, that they inevitably defy intelligibility, and worse: inscrutability. AI-centric Megaproject-controls would democratize the process by making readily available information to public and third-party oversight professionals, whose rights to access would be unprivileged.

- ‘Is the project on time and budget?’

- ‘That depends on what you mean by time and budget.

According to McKinsey, 98% of all megaprojects fail to make budget and schedule. The 20 month slippage reported isn’t particularly helpful without knowing what the average project durations were. If an average megaproject is 10 years in duration, 20 months would be almost 17% slip. That rate would be far above past performances.

Intervention

If ever there was an argument for intervention, the time as now. That’s because the government is reviewing Trump’s trillion-dollar spending bill. If passed, it would engender several megaprojects, needing central leadership. But democrats have not exactly embraced Trump’s bill, arguing that it’s counterintuitive to plan to spend USD$1T on infrastructure, and lower tax revenue USD$1.7T at the same time. If it does pass, it may be pared down to a considerably smaller version of itself.

The intervention I have posted about lately – AI-centric megaproject delivery – is also intended to democratize the process: megaproject general requirements and some general conditions, or ‘soft’ costs, are exponentially higher on megaprojects. This is where the lion’s share of the waste and fraud resides. AI-centric megaproject delivery refers to a semi-automated platform intended to reduce data gathering and analysis and redundant administrative activities by delegating them to AI, which will perform exponentially faster, and with a far higher level of exactitude.

“The change over from data-gatherers to data facilitators will not be unlike the change homo sapiens underwent from hunter/gatherers to farmers and settlers.

AI-centric megaproject delivery is intended to level the playing field, democratize the process, by deconstructing Kafkaesque clandestine power structures that control and skew information for their own selfish purposes.

2011 East Side Access Groundbreaking Ceremony. Why? (actually, ESA started in 2006)AI will do this by making the process more transparent, and involving more robust partnerships with private sector and third-parties. That means NGO oversight consultants and other diverse experts from the private sector – people with no political motivation.

Brave New Megaproject

Perhaps, as AI platforms become more accessible, there will be trickle down adoption into projects less than USD$1B – much in the same way BIM mainstreamed. The result wouldn’t take project controls jobs away, in fact, AI disruption will create as many – and better – project control roles as it replaces.

Maybe far more; because schedulers and estimators are the source of the data. They are essential to the machine learning process. Thus, opportunities for megaproject control operators with experience should spawn upward growth opportunity in the industry, which at present is impoverished of talent, mostly for lack of training and upward mobility in the industry.

“Are megaprojects ever immune to the old adage ‘too big to fail?’”

Accountability

AI-centric megaproject disruption would be a wake up call – better yet, a comeuppance shakeout for megaproject leading Clueless Emperors – the traditional stewards of chronic, epic failures, who always seem to fail with impunity. AI would create an international registry of such villains, to discourage them from transplanting.

Ill-conceived megaprojects can have overwhelming consequences on people and the environment. For example, the rampant clear cutting in Brazil’s Amazon Basin to accommodate over 100 hydroelectric dams poses severe environmental and ecological threats to the sensitive rainforest and wetlands there. No proper feasibility or environmental studies were required to build these dams. Are things that much different in the states? Not in Bears Ears National Monument, Utah, where Trump recently opened 2,000,000 acres to oil drilling, fracking, mining, and other resource stripping activities.

Implementation

AI-centric megaproject delivery is, in large part, project controls: time and budget. Estimating cost and durations. Extant scheduling and estimating platforms may interface with the AI-centric platform by providing (verified) data for AI’s knowledgebase, and continuous updates and refinements through their APIs.

Yet, Algorithms and machine learning are just two of the stumbling blocks AI faces in cracking the megaproject controls industry’s disconnect with reality. Another is fragmentation of data, and lack of a standard platform. AI project controls must therefore struggle with slow adoption; however, before worrying about adoption, or AI takeovers, we’re getting way ahead of ourselves. AI needs to be taught how.

“Some vocations will always be out of reach for AI: attorney, help hotline, politician. And that’s a good thing.

In the first place, it must be understood that AI will never be a zero sum equation where it does all or nothing. It will lend itself better to some industries more than others, as well as specific job descriptions within those industries. For example, the design library of a simple block and plank storage facility will be far less sophisticated and specific than a water process plant. An electrician’s scope of work will almost always require more articulation than a painter’s.

AI will execute some work automatically, and some semi automatically. It will never do all of what it does automatically, and it should not. Once this universal truth is accepted and understood, clear lines between manual, semi-automated, and automated activities can be more readily discerned and the technology standardized.

“AI-centric project control will never replace construction estimators and schedulers: that simply isn’t what it’s meant to do: they will facilitate each other toward higher levels of performance.

In other words, AI will work in tandem with the AEC industry to facilitate megaprojects all the way from conception and feasibility studies, through project build out and turnaround. AI is already making waves in the AE industries to great benefit, which I have posted about some weeks back. Semi-automated machinery and drones are making big impacts in the construction industry, as well, creating comprehensive IoT layers that will benefit and enhance future AI platforms. With all the bandwidth capability we could achieve with AI, there’s no place for the old-school Clueless Emperor led food chain to exist anymore. As we learn how to teach AI, create standardized platforms, and populate its knowledge-bases with our own Big data, AI will eventually become robust enough to facilitate – never replace – project controls folks in their work to great extents. How will it do this? – read on.

What’s Brewing in AI Project Delivery

Before AI can run, it needs to walk. What I mean is that it will take some time before robust, validated data sets can be made available for standardization. Machine learning can begin on individual projects and build up a knowledge base from there. AI will enhance its database exponentially as it grows in size, and utilize what it needs for the future.

Some months ago, I stumbled on ALICE Technologies. Now in stealth-mode, ALICE ( Artificial Intelligence Construction Engineering) is working with builders at generating schedules. ALICE offers four different innovations:

- 4D BIM generated project schedules – ALICE also makes 4D BIM models

- Recipe-based – the machine learning and algorithms you load for today’s project are recipes for future, similar projects

- Parametric modeling, allows for exploring faster and more expedient ways to allocate resources.

- Generative – pertains to the various scenarios ALICE builds and allows side by side comparisons

4D schedules are useful for time v. volume of construction visual representations because they offer a three-dimensional insight into the work progression. That would be especially valuable for modeling complex phasing.

As a Scheduler, I can certainly appreciate the ease with which I could call up ‘packages’ of pre-sequenced and resource-loaded data and roll that into a development master schedule. For example, complex hospital project delivery could benefit from standardized sequencing algorithms from current and past data sets, that are historically elusive and complex.

Parametric modeling- ALICE can crunch resources and sequences of operations toward optimized production rates, and continue to do so, as circumstances and conditions change.

Generative means that there are many different avenues of approach, sort of like what used to be called ‘Reflection,’ or ‘what if’ Schedules,’ in ol’ P3 – on steroids. Instead of one or two scenarios, perhaps five or ten, all with metricized data.

One of the thing I admire most about ALICE is that it is geared toward the building industry, which was a surprise to me: I thought cutting edge technologies were reserved for designers.

ALICE could change that by empowering builders to upgrade their project controls, and tilt the technological playing field back in their direction.

AI-centric Project Controls

AI-centric Project Controls, are a subgroup of a larger platform I call AI-centric Megaproject Delivery. ‘AI-centric’ refers to hub-and-spoke networks, where AI is at the center of project control, management, and other processes. AI would be an impartial facilitator and interface for unrestricted information, such as

- Project financials

- Project progress updates

- Schedule metrics and analysis

- Controlled Inspections

- Design deliverable (drawings, sketches, BIM models)

- Submittal/Approval cycles

to the entities in the AI-centric diagram, above, for which a hierarchy of access levels would be established.

AI is the natural center of the network because

- It will have been taught everything we have given it to learn, and become better than us at it

- It can think through complex scenarios in trillions BPS

- Other than programming, it obviates human error margins

- It is intended to provide a fair and transparent process

- The quality of its work is consistent

- It cannot lie or strategically misrepresent facts

- It never ages out

- It never fatigues or has inactive periods

- It cannot wilfully sequester project information or share in secret

- It has no hidden agenda and won’t play favorites

- It will treat all members as equal partners and encourage members to treat other members that way – which is the essence of P3s

AI and BIM: Dynamic Coordination Partners

If we contemplate fully coordinated and conformed BIM architect and engineer drawings uploaded to AI server: right out of the box – we all know – there is virtually no such thing as a pre-mobilization conformed set. Typically sets are called “60%, 75%, 90%,” or some such; however, these percentages invariably tend to be random, at best, and vastly over appraised at worst.

For AI project controls to do its best work with estimators and schedulers, it needs constructible drawings from which it can derive valid data sets from.. If designers continue to refuse to plot their project deliverables in the schedule, AI can easily do this for them. Designers will go kicking and screaming before they agree to such transparency. Isn’t that too bad?

“Designer whining aside, AI doesn’t play favorites, and will not insulate them from scrutiny.

In a perfect world, design deliverables would be far more represented and correlated with specific scopes of work and resources than the random and inarticulate metrics designers fancy. Preconstruction designer performance would be AI-monitored just as closely as any other program.

Industry thought leader Dan Patterson employs AI in his latest software contribution to the project management industry – BASIS. BASIS uses AI to augment the planning process rather than replace the human planner. BASIS combines AI benchmarking to establish durations, costs and sequence of work, with a very smart way of validating these inputs through what is called consensus-based planning:

AI calibrates the plan, and the HI (human intelligence) validates the plan, bringing a project the best of both worlds. What is more, BASIS literally learns the more an organization uses the tool, and will adjust it’s suggestions based on the level of detail captured and the maturity of an organization’s knowledge and expertise.

In BASIS, there is an emphasis on continual benchmarking, as well, where metrics are applied to actual and forward pass scenarios. They hope to someday standardize BIM, as well as their own project delivery SOPs, into global standardizations. However; standardization may be further off than most of us would like to believe:

A U.S. BIM standard won’t materialize — at least for the foreseeable future. “There isn’t a prescribed structure for [a common set of government practices],” said Roger Grant, program director at the National Institute of Building Sciences (NIBS). “We don’t have one agency responsible for all construction like the U.K.” (Construction Dive).

But the lack of a standard won’t stop AI centric project controls. The BASIS platform is designed to build drawing from its own library – which can begin with one schedule. In this way, it can be said that BASIS is not reliant on Big Data – it grows its own.

Federal Work: Same ____Different Delay

The PMIAA, or Program Management Improvement and Accountability Act, was signed by President Trump, in 2017. It is intended to “enhance accountability and best practices in project and program management throughout the federal government” (PMI), excepting DOD, or ⅓ of Federal spending. The bill is allocated USD$20M over the next five years.

However; this think-tank will only offer theoretical solutions to project delivery. Yet, the industry have the time to wait three-years for PMI to tell it how to adopt ‘newly created best practices,’ none of which include AI.

BIM Driven/AI Utilized Data

- Inputs of material quantities will correlate with labor resources and equipment

From these, a range of durations can be assigned

From the project BIM drawings, material quantities, labor resources, equipment, and durations, AI will query its database of similar projects looking for similar sequences

Where there exists several possibilities, AI will make its best guess, as well as poll the operator for refinements

AI will inform operator when it has insufficient data for trolling background data

When AI completes its operations of thousands of scenarios, it will generate reports in tabular and GANTT charts, and spreadsheets – familiar to project schedulers

AI will publish the reports, and poll the operator through a series of refinements and specifics until a short list of scenarios are generated

From the material, labor, resources, durations, a range of most likely sequence of operations can be derived and draft schedules generated

2 . As AI polls operator through clarifications and refinements, hybrid AI -Human scenarios develop that can be reviewed for conformance manually, by the operator.

AI Generative Designed Schedules

Once AI has a robust enough library of data, it should be able to sequence repetitive operations from basic criteria, and build generative designs, for example:

Calculate Cycles for jumping hoist and crane coordinated superstructure table typical above 5th floor, below 57th

Assume –

2 day bar and form work

1 day pour

7 floors clear of working platform above, minimum

28 days curing

AI-Centric Pre-Construction Schedules

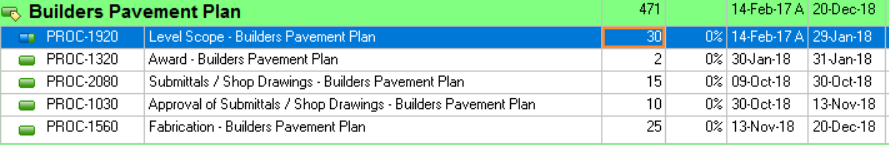

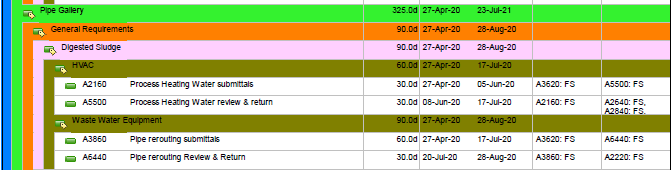

Pre-Construction activities lend themselves well to working with simple algorithms. This is because many preconstruction sequences are largely predictable, and could be easily standardized.

The following illustrates a basic submittal through fabrication cycle:

Pre-Construction | Production | Close-out |

Level → Award→ Submit→ Approve→ Fabricate→ Deliver | → Install | → Testing → Sign-off

The activities could represent any trade. Additional submittal/review cycles may be repeated, as necessary. As AI queries BIM files for program and scope, it will discover and associate trades and activities that it will build standard sequences and durations from, as well as assign resources and equipment to. It will also flag any unique, or isolated sequences that require controlled inspections, or special operator training, for example.

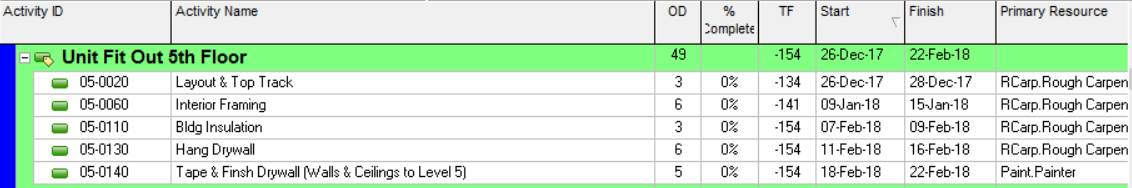

If AI knows there are gypsum assemblies it can fill in the blanks:

Standard Sequence Example

Standard resources for gypsum assemblies would be drawn from: framers, electricians, plumbers, insulators, sheetrockers, tapers, and painters. Effort can be estimated from BIM QTO volumes, and verified. The operator tweaks sequences globally until the schedule is optimized and baselined.

AI-Centric Production Schedules

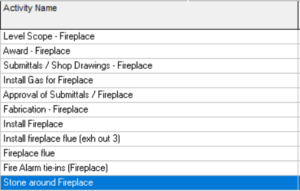

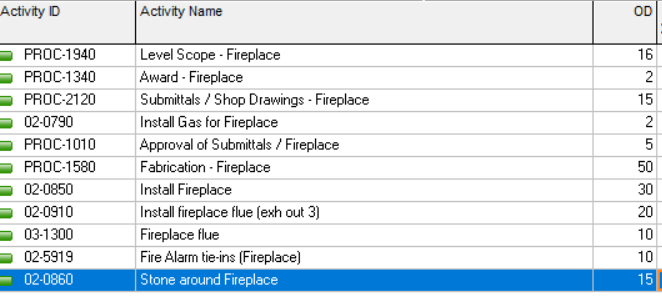

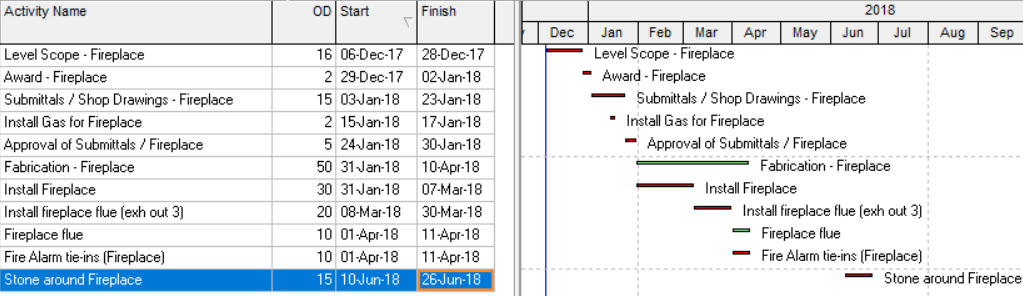

Just like Pre-Construction, many submittal through production or installation cycles are – more or less – standardization-ready. For example, as AI discovers a fireplace on a project, it is able to make a number of basic activity assumptions regarding related activities and sequences. Drawing from a database of similar projects AI renders the activities into a logical sequence of installations:

AI will calculate durations and resources drawing from BIM quantity take-offs (QTOs), and compare them to similar sequences in its database:

AI can now generated a bar chart for the sequence

Analytics & Forensics

No megaproject should be allowed to commence without a proper understanding and implementation of a wholesome analytic and forensic program, or rather, the data that Clueless Emperors are terrified of: metricizations of their handiwork.

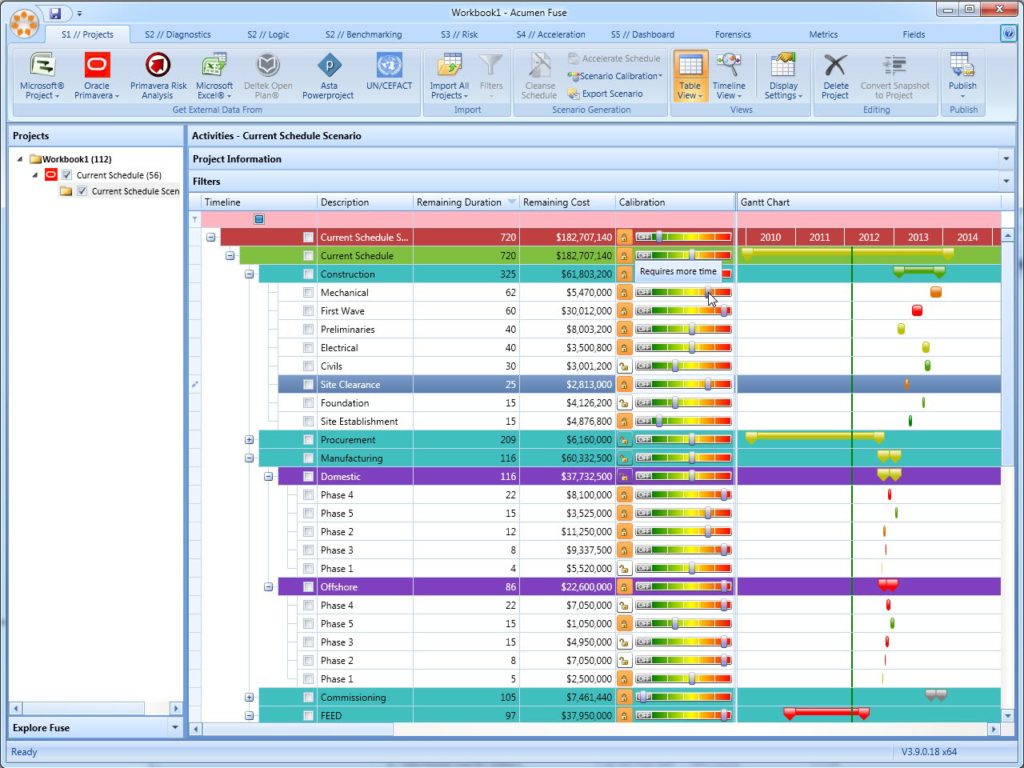

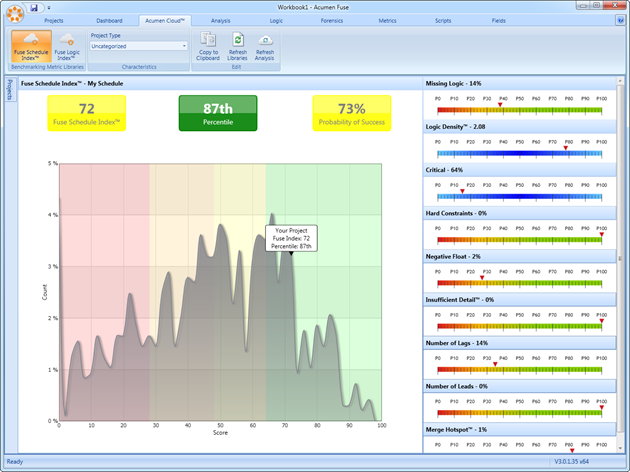

Deltek’s Acumen Fuse maintains an online database including tens of thousands of construction schedules sorted according to type of construction, and benchmarked against similar projects. This database, or a similar one, can be enhanced exponentially with more construction schedules and more industry buy-in. This is the first step toward standardizations derived from Big Data.

From BIM output, AI will run scenarios to determine mean activity durations and relationships. It will then generate timelines, or GANTT charts representing the roll-out of the project. These will be coded and grouped both with standardized WBS and project codes, for example:

Area, Process, System, Division, Trade, Activity

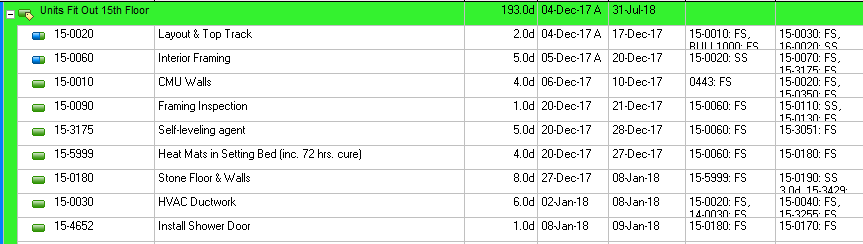

AI can derive from the above durations for related trades and the order of installations. If the sequences repeat each floor, global patterns will be assumed. Such a schedule will populate rapidly. The above processing plant is an example of a sequence that would not repeat, and be difficult to source from existing databases. Operator effort would be considerably higher. If complex plants were all built the same way, that wouldn’t be true. Therein, an argument for standardizations. A more simple trajectory describes a basic residential fit-out:

Duration, Predecessors, Successors

Returning to the more familiar example above, AI will call up resources and cost from data it has collected from BIM QTOs, as well as a global database.

Operators will be required to load specific cost and resources. AI will then develop and correlate these with Resource Assignments and Cost Assignments. The ongoing interface, check-ins, and oversight between AI and project control operators are the essential backbone of AI-centric megaproject project controls.

Resources – vendors and subcontractors – would interface at the secondary level – below prime contract members, or through the construction manager.

Criteria, such as start and finish dates, constraints, and other variable contract information will be input at the beginning of the survey by the operator.

AI-Centric Close-out Schedules

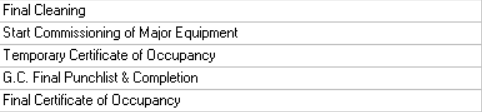

Similar to pre-construction schedules, close-out sequences are also fairly predictable, and are standardization-ready for AI to learn the specific General Requirements for the respective trades and programs.

General Requirement Close Out activities are fairly uniform across multiple building types and uses:

Standard Close-out Sequencing

General requirement Close Out activities will be keyed off of preconstruction submittal activities, as each installation requires at minimum a rough or visual inspection. Other trades may have controlled inspections, and require specific types of documentation for

- Testing & commissioning

- Training

- Owner Maintenance Manuals and Warranties

For example, if there is ACM remediation, AI will call up specific sequences for ACMs from its libraries and insert them into the timeline.

Project Lifecycle

One of BIM’s strengths is its ability to plan and monitor assets throughout their lifecycle – including maintenance and replacement programs. These programs are an extension of the project delivery, and have direct ties traced back to specific activities and sequences. Between AI, and the IoT, these processes can be largely automated or semi-automated.

AI-Centric Mitigation and Recovery Schedules

Although risk assessments play a critical part of project delivery, they are vastly underused and misunderstood in the AEC industries: especially the design industry, which is characteristically naive to budgeting and value engineering. AI-centric project control will utilize risk assessments beginning with a Level I schedule, and refer back to the registers with every update.

AI will monitor all activities, as progress is updated. Trip-wires will generate alerts where performance is off, or deadlines are breached. AI could utilize platforms such as Deltek Acumen 360, which is a schedule acceleration program that uses inputs, such as risk and probable outcomes, to recommend avenues of approach to mitigation and recovery. Risk will be assigned in risk workshops. AI will generate the risk assessments (RAs) and use them as a basis for forward pass and acceleration scenarios.

Single source platforms will be the most robust, and least likely to deprecate. Acumen 360 can implement risk scenarios through its own Deltek proprietary module, Acumen Risk. Both risk and acceleration plans can be executed within the Deltek family, and will not require any special parsing.

Acumen Fuse 360

The beauty of Acumen 360 is that you can model and tweak different risk profiles or scenarios in the same window, and view the results before an action plan is agreed upon. 360 can model as many acceleration simulations as there are risk-profiles for in the register.

AI-Centric Schedule Build

Operator input project criteria: start date, end date, constraints

BIM Output – quantity takeoffs, and raw data for assignment in the schedule

Upload to AI-Centric Server

Generate activities with duration, sequence of operations, and costs and resources

Populate CPM timeline with grouped and networked activities

Check logic statistics for clarity

Check schedule for success probability and generate histograms

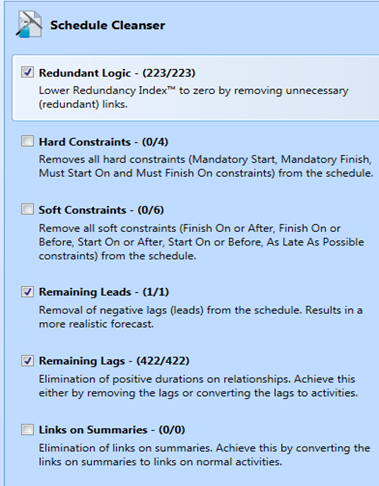

The histogram above indicates an 87% percentile integrity, with 73% probability of success. Next is to run the schedule through an optimizer, such as Deltek Acumen Fuse Logic tab ‘Cleanser.’

Cleanser shows us what can be eradicated in a single keystroke. The schedule logic is now optimized, and ready to incorporate risk assessments and potential acceleration scenarios.

Conclusion

Although AI technology is relatively nascent in the building industries, the background data it would use to generate cost estimates and schedules is already in circulation, albeit fragmented, unverified, and non-standardized. Platforms, such as Deltek Acumen already utilize this wealth of data to power their forensic and analytical engines.

Given the high redundancy rate of standard constructions, it’s not such a big step forward for AI to takeover the data gathering/ data crunching that estimators and schedulers laboriously toil through every day, freeing them up to perform manual activities and others that are not well suited to AI execution.

By reallocating resource assignments to AI, assistant PMs, superintendents, and other managers can address more complex issues and provide more services, that are typically not performed for lack of resources. This redelegating of responsibility would have an immediate positive effect on the standard of project delivery, which can only go up.

AI disruption could make substantial improvements to the industry by overturning outdated notions and modes of prosecution, and converting to an organizational system that features accountability and expedience. Such a system would minimize administrative waste, and make a distinct impact in the way megaprojects are structured for delivery.