What are we to make of recent advances in semi-automated robotic construction technology, like the example below, of a bricklaying Semi-Automated Masonry rig?

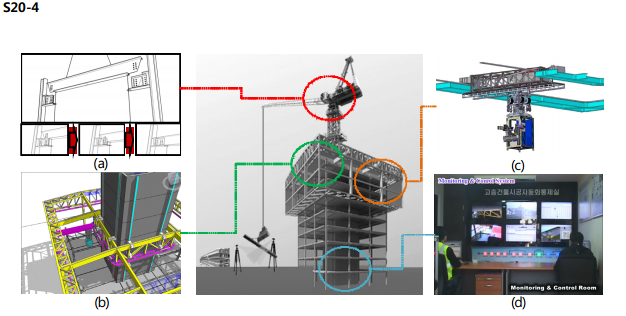

or this robotic crane, that can erect structural steel framework all by itself, while a project manager looks on, over a live feed, at a remote location.

Construction Robotics’ SAM is receiving great press, and deservedly so. It passed recent dog & pony show muster with flying colors. It seems to be the darling of the World of Concrete, receiving the 2015 “MIP Most Innovative Products Award,” but best of all, it seems to deliver as advertised, despite the ticket price – $650,000, + training and support package.

The first model was in Beta tested, in 2014, and the prime-time launch was promised this year, yet sightings gave been scarce since the last press release (an award), in March of this year.

Semi-Automated Robotics is not the only firm cloying for market-share in the construction industry. Komatsu rolled out its Intelligent Machine Control (iMC) technology in January, of this year (this video worth it just for the soundtrack). In all seriousness, there is huge potential here, especially for the earth moving and mining industies.

iMc provides fully automated operation, from rough-cuts, through grading. The cab operator, or rider, pushes a few buttons. He does not need an operator’s license. Thus may a supervisor, laborers, and licensed operators be foregone, in deference to the robot and rider. It was noted in the article that the robot increased a licensed operator’s productivity only 13%. A primer in the art of excavation and grading would explain why.

The iMc, which can retrofit four Komatsu dozers, and one excavator, allows excavation to grade with only a low-skilled operator, as the machine follows its sensors to follow the pre-programmed cut. There’s no need for a foreman or a supervisor, a drone takes care of that. The machine operates by GPS. It uploads in real-time to a remote site, where a 3D map is generated.

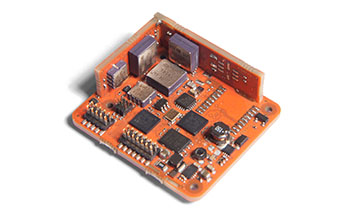

The most impressive recent advance in the equipment is the redesign and transfer of the blade mounted sensors, which were problematic, to another system, and a more compact and secure antennae systems. This was achieved with an enhanced Inertial Measuring Unit (IMU+) (like a gyroscope, or accelerometer) along with stroke-sensing hydraulic cylinders that perform many basic operations 100s of times faster than manual or traditional methods. It is the same technology used for defense system hardware.

An IMU:

The need for robotics in construction is high in Japan, where enough experienced operators are hard to find, especially in preparation for the 2020 Tokyo Olympics. Thus has Komatsu begun a vigorous leasing program, this year.

Soon after I first knew of Construction Robotics as a start-up, around 2007, I began to hear the old saw that such robots will eventually cost the jobs of brick-layers and mason tenders. I’m not so sure. Any bricklayer worth his salt will never go wanting for a day’s work. The same is true for any skilled trade, where 83% of contractors have resource difficulties. Only when the work stops, will the bricklayer go jobless. Besides, most automated robotic machinery becomes superfluous when working around existing conditions or retrofit work.

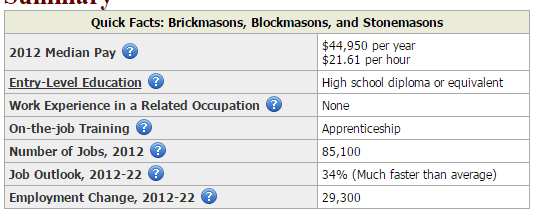

The manufacturer states that “it is estimated that over the next seven years, there will be 40% growth in the number of masonry jobs (BLS),” however, the statistics actually project a 34% increase over 10 years. In 2012, there were 85,000 mason jobs in the US. Thus, by 2022, there will be 29,000 more mason jobs created, or 3,000 jobs each year. By comparison, there are 617,000 carpenters. Point being; bricklaying is a small sub-sector of the overall industry, in which a huge investment cannot be taken for granted.

“SAM is a high-level producer that will bring young, educated, technically-skilled workers to the masonry industry.” My guess is that at the median yearly wages for a bricklayer of $45K/yr., that highly educated techies who wouldn’t know a trowel from a shovel are not going to be lining up to be masons. I should also think that an old mason would be humiliated working alongside a SAM, but better that, than no work at all.

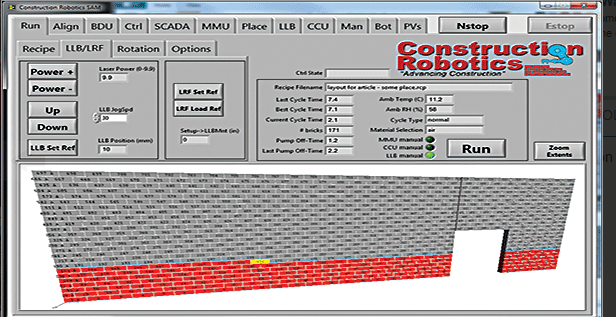

According to the manufacturer, if a mason can use a Smartphone, he can program the SAM. Take a look at the interface screen below, and I’ll let you be the judge.

It’s got that ‘0ld 90s DOS look, for sure, although it looks vey sophisticated, nonetheless

Here, in New York, a Tender would likely have to mix the mortar in the machine, which a Bricklayer cannot do, and load his bricks into the hopper, which a Bricklayer may not do either. Unions with similar contracts will require the same personnel on site, regardless of whether they are awake the whole time. This could be a deal breaker.

From this point, it is pretty impressive to see the machine lay a perfectly plumb and aligned wall, although a Bricklayer still has to be there to strike the joints, tie-backs, etc., which a Tender may not do. Effectively, a contractor is paying his men to stand around and watch 90% of the time, and assist the robot 10% of the time.

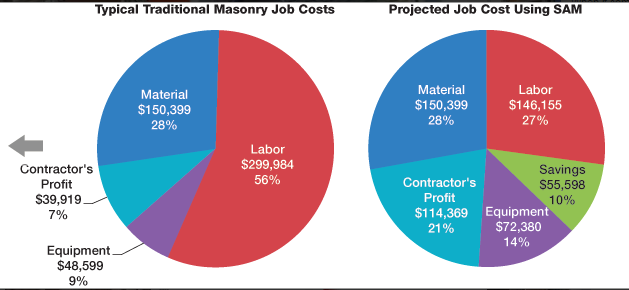

Even so, there may be a point at which the productivity of the semi-automated crew becomes a good return of investment, and I’ll wager that the straighter the wall and fewer there are corners and transitions, the sooner that investment would be realized. Construction Robotics provides the following charts on their website:

How productive is it? It can lay up to 2,500 bricks per day, or twice to thrice the productivity of today’s Flintstone methods, yet the manufacturer estimates savings of 20-30%, due to the increase in productivity. Despite the notion that , the jury is still out on whether Union members will embrace it, as the owners will surely love it. Some other benefits of implementing the equipment is

- Less physical exertion/wear & tear on the men

- Fewer injuries and accidents

- Virtually no mistakes: SAM only does what it is told to do.

Construction Robotics’ SAM is receiving great press. It seems to be the darling of the World of Concrete, receiving the 2015 “MIP Most Innovative Products Award,” and has received two NSF grants. The first model was in Beta testing, in 2014, and the second model was to be launched this year; however. I have not noticed it.

Indeed, judging from the search returns for “semi-automatic+construction+machinery,” only Construction Robotics’ SAM, and Komatsu’s iMc are bandied about in the media, i.e., it’s going to be a while before automated field work is mainstreamed.

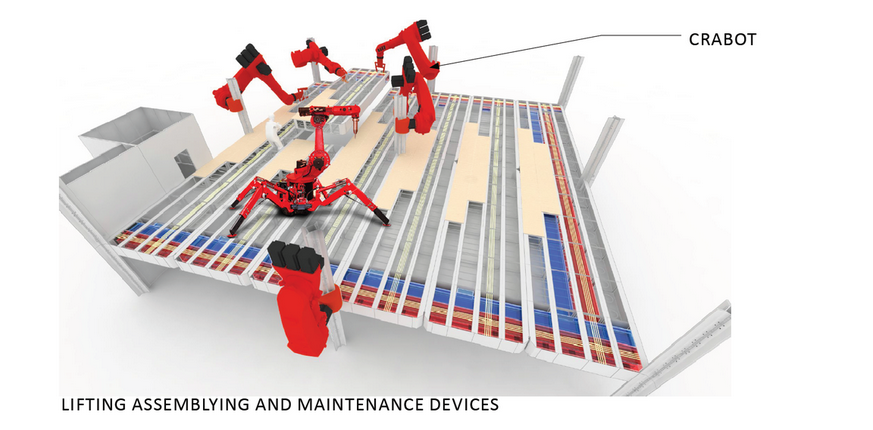

But that doesn’t mean it’s non-existent. Consider a robot that erects steel buildings. Ona smaller sclae, “crabots” were proposed build the new Google Heatherwick HQ before LinkedIn scuttled those plans, last month.

For my money, there’s nothing more satisfying than a properly hand-laid brick wall, with consistently struck joints, tie-backs, and flashing. The difference between a hand-laid and robot wall is in the perfection of tolerances met by the robot’s wall, in comparison to the man’s wall. This can be objected to on aesthetic grounds, the argument being that the perfect wall lacks the human element of imperfection that makes mans’ masonry so natural and pleasing.

However, quality hand-laid masonry is a dying art. Highly-skilled bricklayers are extremely hard to come by. This is plainly evident in pre-War brick structures, as compared with the advent of glazed white-brick apartment houses of the 1960’s, and today’s ubiquitous atrocities, particulary in restoration, in which SAM must be a non-starter: the machine can never replace ‘in-kind,’ or match the charcter and integrity of an existing structure.

Brick was replaced long ago as a primary structural element in building construction. It is considered to be cost and maintenance prohibitive, and a poor insulator – which is antithetical to carbon-conscientiousness, thus there may not be as great a need for bricklaying in the future. Indeed, only 7% of all construction industry is composed of block masons and bricklayers; the majority of these are CMU block masons.

Down the road, this SAM will become obsolete, to be replaced by a better SAM, or even a fully automated masonry utility (no masons), at a considerable investment that will likely be accessible only to the largest masons, whilst the last remaining bricklayers quietly continue to ply their craft, without need for upgrades or someone to butter their bricks for them.

This is where some may object to automated construction work on moral grounds, in the same way they did when robotics took over the auto industry. We all know how much traction that argument gained. With a mere 85,000 masons in the US, I doubt there will be anything more than a negligible objection heard, or any sort of consensus expected, from this small constituency.