Bringing Building into the 21st Century with Agile MEP Coordination

“Agile MEP Coordination can be a game changer only with team buy-in.

No process seems more elusive or esoteric to your average construction professional than the mechanical/electrical/plumbing (MEP) coordination phase of a project. The process takes place as a means of assuring that a minimum of conflicts, or program interference – mostly above the ceiling, rear their ugly head in the construction phase, when there is little time to resolve them, and perhaps change orders for tear-out and replacement. Woe to the project team who forgo this process. This is the incentive for more efficient project delivery platforms, one of which is Agile MEP Coordination.

“Agile MEP coordination paired with Autodesk’s Autoroute feature could be a game changer for the building industry, if only they were paying attention.

MEP coordination is often a prolonged and tedious process that can create delays in project timelines. Fragmentation of information and poor communication is often to blame for this. On a good day, a coordinated set of drawings is vetted before material is fabricated; however, that is often a luxury that a project schedule can’t afford to wait for. Agile framework methods developed for, and used by, software development teams can streamline the effort, and ensure optimization. This is because of the striking similarities between MEP coordination and Agile frameworks.

“Architects invaribaly can’t cut the clash-detetcion mustard

Like software development, MEP coordination consists of a backlog of activities to be performed by several distinct team members. In construction the issues are chiefly shop-drawings that schematically represent the relationship of their work to project layout in specific areas (as opposed to general). Their drawings will later be overlain onto the project layout, alongside other trades, to be checked for conflicts. Each shop drawing from the respective trades must be free and clear of adjoining works. Once it is, it can be folded into the coordinated drawing set. At the same time, but to a lesser extent, the design team also reviews the shop drawings; however, coordinated drawings are generally not considered a required submittal, as they have more to do with means and methods.

Agile MEP Coordination: get ready to scrumble!

Along the way, and during the review process, there will be resubmittals, and even design changes to facilitate the MEP accommodation of the immutable components of the design; such as location of ductwork – which has the least flexibility, ceiling height, light fixtures, grilles, et al. Traditionally, trades conduct their work independently, only to join forces at job meetings. The downside of this is that much time is needlessly wasted – time that could have been saved with on-line collaboration and troubleshooting. Instead f waiting for weekly meetings, daily meetings could resolve conflict on the fly.

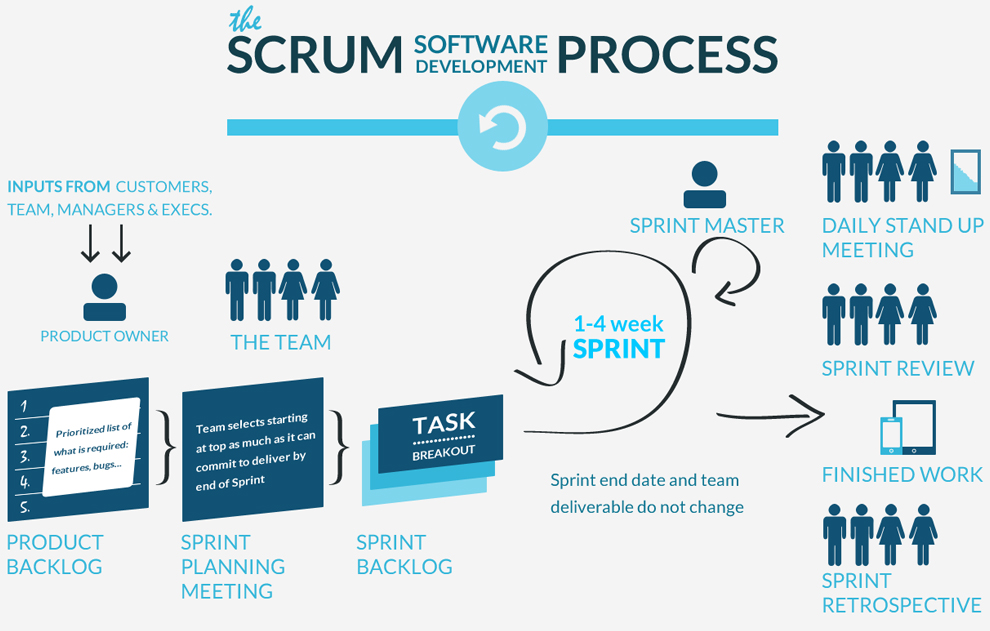

Agile MEP Coordination will be reliant on close online collaboration through tools such as Trello, which works with Scrum. Consider the Scrum flow-diagram below, which we will transpose for our purposes to represent the MEP process:

The Agile MEP coordination product backlog consists of one issue at its conclusion: the coordinated drawings.

The Sprint planning meeting will prioritize the incorporation of each trade’s drawing issues into the coordinated drawing set, which begin with the mechanic’s duct shop drawings and equipment schedules.

The Sprint backlog will identify each shop drawing to be issued, and its place in the hierarchy of the process. Unlike software development, this process must be sequential, else there is risk of a domino effect on other program, which is one difference between the Agile MEP coordination effort and Scrum frameworks: software has numerous complex front and back-end modules that can be developed simultaneously and independently, and later integrated according to the product manager’s plan, whereas MEP works are all inter-related: a change to one may affect all, which is why the process is better approached sequentially

The Sprint backlog will continually be replenished with revised issues until it can be said that the drawings are integrated. In the first two-weeks, shop-drawings will be prepared and submitted to the design team and MEP captain – usually the mechanical project manager, who will check for conflicts. As conflicts arise, he will red-line the drawings and return them for revision. We might call this the Sprint-review.

At such time as elements are coordinated into the master plan, respective trades may begin dimensioning their fabrications based on actual field conditions, as opposed to schematics. This is the difference between schematic shop drawings and dimensioned, or fabrication drawings.

Once all trades have been integrated into the MEP master set, the product is considered delivered, or rather, fabrication can begin.

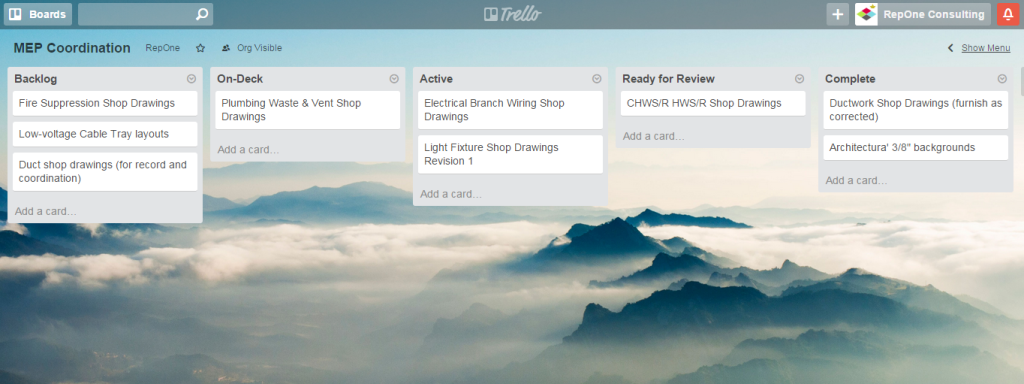

To demonstrate my point, I have prepared a board on Trello that illustrate the process.

We see in the back log that that Fire Suppression, Plumbing Waste and Vent, and Cable Tray submittals have not yet been issued.

Plumbing Waste and Vent shop drawings are on-deck, or next to begin

Electrical work is in revision for the present week.

Chilled hot/cold water shop drawings have been submitted, and are in the process of overlay and conflict resolution.

Architectural backgrounds have been provided by the design team.

Ductwork shop drawings have been approved (FAC), and only require reissue for record.

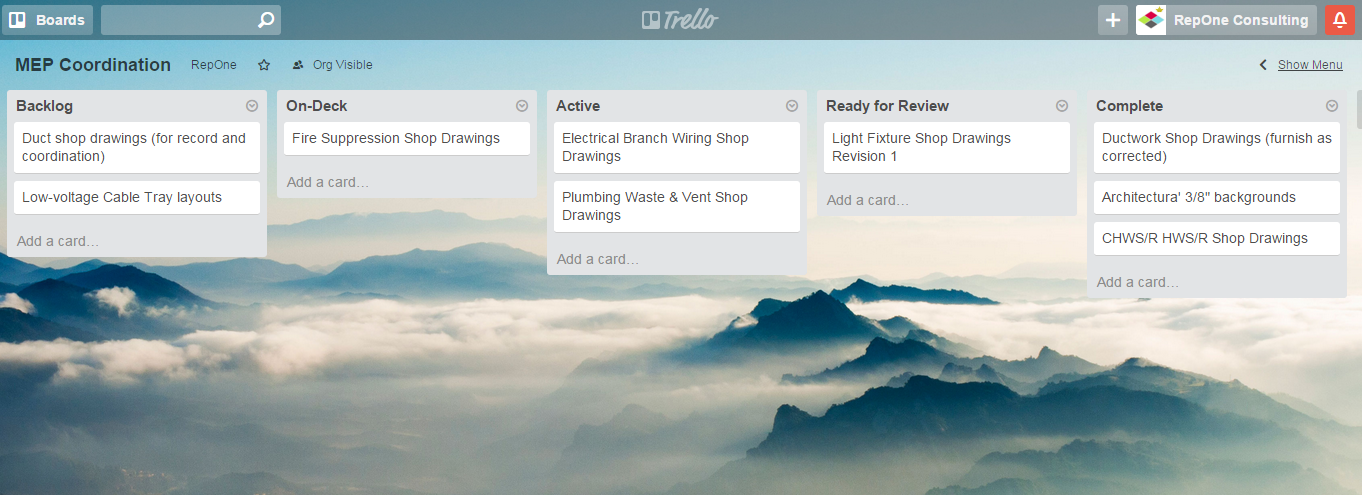

As we advance to the following week, we see the sprints move from left to right, reflecting actual progress:

Using the Trello dashboard, team members can upload files, and comment in real-time. If there is a chat plug-in, such as #Slack, they can have working meetings on-line, as well. The Scrum master alone will have administrative rights to the board – only he can move a card from one list to another.

With this element of control and team collaboration, the MEP coordination processes for many complex projects could be substantially foreshortened, and the process considerably streamlined, as compared to the fragmented and elusive free-for-all that typically comprises the effort.